The greatest benefit seems to be in complex control of the factory. A SCADA system is extremely useful for all of the workers on the production team. The operator has the main overview of the production in real time, the technologist is able to reconfigure the recipes from the office when it´s necessary, for maintenance it is important when and why the failures happened and the shift leader can check who is responsible for that.

Industry 4.0, IIoT and Connected Manufacturing

Barbora Plaminkova | mySCADA Technologies

Are you familiar with the term Industry 4.0 and if so what does it mean to you and your company?

Yes, we are very familiar with this term and we are one of the first companies that not only talks about it but also has some real examples of using it. We were ready for the fourth industrial revolution for a while but the truth is that this newly established notion (Industry 4.0) and its massive promotion helps us explain to our customers what our software is capable of.

Industry 4.0 is reflected in all industrial fields and for each of them could be beneficial. Read more about: https://www.myscada.org/industries/

How is your company set to benefit from the buzz about the factory of the future?

In general, we understand this term as the factory which is able to function more or less without people. It means the factory is able to control itself - check if the orders are correctly made, have the right weight, shapes, ingredients… Some believe that this factory could even change the orders depending on the market situation.

In our area, we are able to supervise the factory as a whole with our software, the software controls everything for the employees and they can focus on optimization and improvements of the processes.

mySCADA is glad that more and more institutions and individuals are using terms such as smart factories, factory of the future, Industry 4.0 or IoT because it raises awareness, which means progress in the whole Industrial automation.

What applications of the Internet of Things (IoT) are you or do you plan to implement in the near future?

Our system is completely ready for Internet of Things. Our products (software and hardware) can be used anywhere. Already now, our software is used for smart parking in cities as well as for home automation. Currently we are working with a large telecom company on a brand new conception – Visualization of IoT Network.

How do you interpret the term “Connected Manufacturing”?

Our system is completely ready for Internet of Things. Our products (software and hardware) can be used anywhere. Already now, our software is used for smart parking in cities as well as for home automation. Currently we are working with a large telecom company on a brand new conception – Easy visualisation in IoT Network.

Do you think Industry 4.0 will bring more (but different) jobs to the industry or will it result in a large loss of employment?

In our opinion, a similar amount of people will be needed but with different skills and abilities. Less employees in production means more of them in other company departments. The greatest issue in the future is which educational institutions realize that as the first ones. These graduates will have an unbelievable advantage.

Can you give us some examples or scenarios that help to convey the benefits of Industry 4.0 to others in your industry?

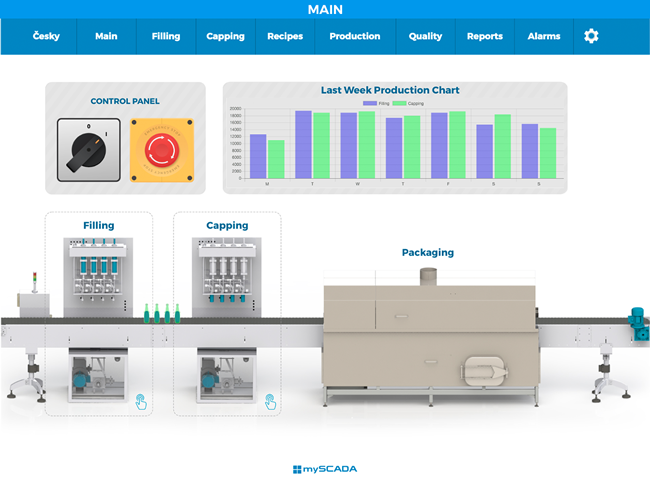

The greatest benefit seems to be in complex control of the factory. A SCADA system is extremely useful for all of the workers on the production team. The operator has the main overview of the production in real time, the technologist is able to reconfigure the recipes from the office when it´s necessary, for maintenance it is important when and why the failures happened and the shift leader can check who is responsible for that. Quality controllers simply see if the procedures were followed and production managers check finished orders and the final productivity. Important data are selected and sent to TOP management and could be submitted to the owner.

See how simple it is to use SCADA here where mySCADA is cooperating with the panel manufacturer.

How about scenarios to convince the general public that Industry 4.0 is a good thing for their future?

In general, Industry 4.0 is a good thing. It will cost a lot of money to adapt to, but the truth is that it would be necessary. The companies that are not able to adapt will have real trouble to stay competitive. We highly recommend adaptation as soon as possible although some complications are associated with it. Here are some of the inconveniences with implementing I 4.0 technologies and how mySCADA deals with and help the clients go through the change as simply as possible:

1. High investment to implementation

mySCADA brings different products for differently sized companies while maintaining all functions. Once you buy the product, no other paid additional charges needed.

2. A large number of communication data

The real time data are collected and have to be saved as well. mySCADA is able to collect a huge amount of data with no trouble, such as slowdowns. It always depends on the size of the project but in general, mySCADA can recognize thousands of logged data per second.

3. Save the collected data

After data logging, mySCADA selects and shows them in a summary table/graphs. It helps to not only have them but also understand them properly.

More about our reporting tool: https://www.myscada.org/myreports/

4. Standardization

Most of the systems are adaptable only for some protocols/operating systems and to start using SCADA (or other I 4.0 technology), which means investing in technologies that are compatible. mySCADA is compatible with most protocols available and also with most operating systems, which saves cost and time.

More about mySCADA visualization and its specifications: https://www.myscada.org/mypro/

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product