Increasingly in the age of energy management in process, manufacturing and BAS, the need for companies and organizations to not only record and manage the energy or water usage but also sub-meter, an Ethernet transmitter with totalizer function is essential.

Twin Totalizers Send Your Flow Meter Pulse or Analog Signals to the Network for Metering or IIoT Remote Monitoring

Mike Moore | Acromag

Many applications call for converting flow meter pulse or analog DC current signals to Ethernet network for extended remote monitoring and control application. Increasingly in the age of energy management in process, manufacturing and BAS, the need for companies and organizations to not only record and manage the energy or water usage but also sub-meter, an Ethernet transmitter with totalizer function is essential.

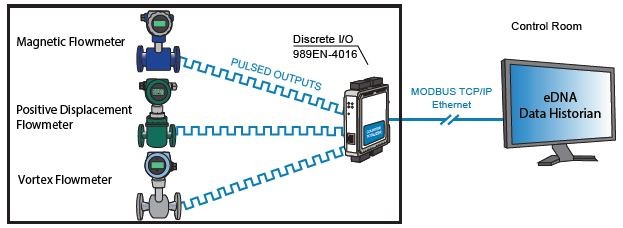

For flow meters with pulse output, Acromag's 989EN-4016 16-channel discrete I/O with counter/timers to Modbus TCP/IP transmitters are widely used for I&C, remote monitoring and sub-metering applications. One popular application of university power plant steam cost calculations is achieved by sending pulsed outputs from flow meters to the 989EN-4016 with discrete inputs and signal counters configured to totalize and convert to digital data sending over the campus network to the central control room data historian.

Other applications include water usage sub-metering, liquid filling and transfer processes including using the 989EN-4016 discrete outputs for limit alarms and control, making the 989EN-4016 versatile and a value priced solution at $320.00 in the US market for 16-channels discrete I/O with counter/timer over Ethernet.

Customers appreciate the ease of use built in web browser configuration software tool and ability to remote in over the internet. The 989EN-4016 has 8 configurable counter/timer channels with 32-bit up/down pulse event counters, 16-bit periodic timers for last pulse state and momentary latch alarms for each counter. Consistent with Acromag industrial grade signal transmitters, the 989EN-4016 has rugged operation features such as over-temperature, over-current and over-voltage output protection and wide operating temperature.

For flow meters with 4-20mA current loop output, Acromag's 993EN-4016 16-channel DC Current input to Modbus TCP/IP transmitter with configurable integration/totalization functions is used. Each channel A/D is 16-bit high resolution with a fast 8mS scanning rate of all 16 channels. Sample averaging is software configurable as well as scaling registers on all channels along with automatic calibration and self-test feature. The industrial grade 993EN-4016 is UL/cUL listed, with typical accuracy of 0.05%, operating temperature of -40 to +70C, and at $835.00 for 16-channels a value prices energy monitoring Ethernet transmitter.

So if you need to extend your flow meter measurements beyond local PLC and add totalization function to the data, call on Acromag to discuss your application and how the 989EN discrete I/O or 993EN analog current input twin totalizers can provide the conditioned energy metering information you need.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product