Artificial Intelligence in manufacturing is achieving a wider degree of acceptance. Smart factories will drive $37 trillion in new value by 2025, giving rise to new research projects. The technology is now . . . the research is on the move.

Artificial Intelligence in Manufacturing

Artificial Intelligence in Manufacturing

Len Calderone for | ManufacturingTomorrow.com

Artificial Intelligence (AI) is changing many industries, including manufacturing. We will see AI managing manufacturing, quality control, materials waste and maintenance, as well as shortening design time.

AI is the replication of human intelligence processes in computer systems. These processes include the procurement of information and the use of rules for using the information, thereby reaching fairly accurate or positive conclusions with the ability to self-correct.

The first uses of artificial intelligence are already in regular industrial activities, such as language recognition to accomplish basic tasks, recording environs using cameras, laser beams, or X-rays, and providing virtual personal assistants for logistics. Last year, 62 percent of large corporations are utilizing AI technology.

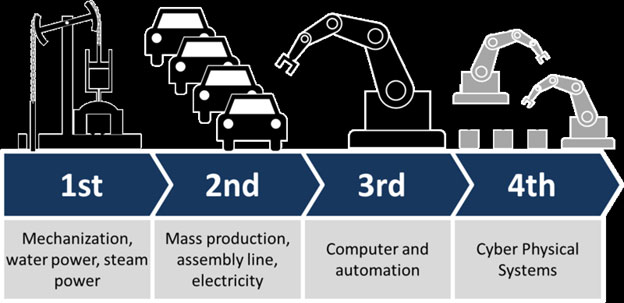

Using big data, AI is giving Industry 4.0 huge improvements. Intelligent software uses the high volumes of data produced by a factory to identify developments that can be used to make manufacturing processes more economical. Factories are continuously adjusting to new conditions and optimizing operations without operator input.

Graphic: Wikimedia Commons

Employees at many factories still inspect parts themselves to spot defects, which is incredibly tiring, but deep-learning algorithms takes half a second to inspect a part. This technology can pick out minuscule details and defects far better than the human eye.

When combined with a cloud-based data processing system, defects are promptly identified and a response is automatically directed.

Maintenance is an area where cost savings can be derived. The cost of machine downtime is excessive. The International Society of Automation states that $647 billion is lost globally each year due to downtime. While many manufacturers are using some method of preventive or predictive maintenance, AI can steer companies to a new way to increase productivity. Instead of predicting impending equipment failure, AI-enabled prescriptive maintenance is exceptional in that it generates outcome-focused recommendations for operations and maintenance from analytics.

Using what’s called generative design, AI is being used to create thousands of component designs greatly reducing the time it takes for manufacturers to test new concepts. Using AI software and the computing power of the cloud, generative design enables engineers to create thousands of design options by merely defining their design challenge, such as inputting basic parameters such as height, strength, supporting weight, and material options.

In addition to monitoring challenges in the air, AI can also reduce the damaging emissions pumped into it in the first place by manufacturing facilities. AI is a new tool to help us better control the impact of climate change and protect the planet. AI can sense the environment, think, learn, and act in response to what it senses, using programmed objectives.

AI has helped researchers achieve about 94 percent accuracy in identifying tropical cyclones, weather fronts and atmospheric rivers, which can cause substantial rain. These are often difficult for humans to recognize on their own. By improving weather forecasts, AI can help companies that depend on weather forecasts, such as manufacturers and logistics companies.

Analytics combined with AI will document and evaluate everything, including the early stages of quoting and launching a supply chain. AI will reduce supply chain forecasting.

Previously unused data can be constantly gathered and sorted by AI, exposing knowledge that was too time-consuming to analyze in the past. This data can also be used to communicate within the supply chain, limiting delays to a minimum as real-time updates and requests are immediately accessible.

According to a study by the World Bank, 98% of the world’s waste is delivered to landfills, dumped into the oceans or being incinerated, although a large majority of consumables are recyclable. The reason for this is due to the high level of contaminants found in recyclables today, making former clean material essentially unrecyclable and financially unmarketable. Not only does AI help identify waste that can be recycled, it has a one percent defect rate preventing waste.

Cloud-based machine learning allows manufacturers to simplify communication between their many branches. Data collected from one production line can be interpreted and shared with other branches to automate material purchases, maintenance and other operations that were previously done by hand.

62 percent of business buyers want manufacturers to anticipate their needs. That's unbelievable in and of itself, but it's also problematic for customer service, as 63 percent of customers claim that customer service isn't as fast or easy as they require. Customer service needs increasingly advanced technological capabilities to span the customer expectation disparity.

Customer service is poised for a revolution with a 143 percent growth in AI anticipated in the next few years. AI is new to customer service departments, as fewer than a fourth of organizations are using it today. AI strategies are positioned to unburden repetitive, time-consuming tasks from customer service agents. Gathering basic information from a customer is the most common AI use.

Chatbots, which is AI technology that simulates voice or text-based conversations with humans, automate routine tasks. Today, only 23 percent of service departments are using chatbots, with high-performing customer service departments using chatbots two times more than under-performers.

AI will influence manufacturing in ways we have not yet expected. As AI takes over the manufacturing plant and automates tedious and routine human tasks, workers will get to focus on intricate and inventive tasks. While AI takes care of routine jobs, humans can focus on steering innovation and steering their business to advanced levels with expected profits to increase by 36%.

Using AI, manufacturers will be able to create quick, data-controlled decisions while facilitating enhanced production results. Management will be able to improve process effectiveness, reduce operational costs, expedite superior scalability, and facilitate product development.

Artificial Intelligence in manufacturing is achieving a wider degree of acceptance. Smart factories will drive $37 trillion in new value by 2025, giving rise to new research projects. The technology is now . . . the research is on the move. How will your manufacturing company move forward with the technology?

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product