From a 6-mile high view of the world, the AM process is less wasteful than conventional subtractive manufacturing processes, and allows for improved resource efficiency.

Promoting Safety & Sustainability in the AM Process Chain

Promoting Safety & Sustainability in the AM Process Chain

Joseph Crabtree, CEO | Additive Manufacturing Technologies Ltd

The concept of sustainability and safety in the use of additive manufacturing (AM) in general has been an area of discussion for a few years now. However, with the understandable shift in focus towards post-processing when using additive manufacturing technologies — which is today rightly considered to be a key barrier to the uptake of AM for production applications due to cost and time implications — the time is right to look at sustainability and safety in this area of the AM process more forensically.

Additive Manufacturing and Sustainability

In a nutshell, AM enables more cost-and resource-efficient small / medium scale production and is forcing manufacturers to reassess their approach to manufacturing. As such, it is a disruptive technology, and as it opens up the ability to manufacture parts and products with almost unlimited complexity and atypical geometries and features, it is also an enabling technology.

From a 6-mile high view of the world, the AM process is less wasteful than conventional subtractive manufacturing processes, and allows for improved resource efficiency (manufacturing processes can be redesigned for AM); extended product life (through approaches to repair, remanufacture, and refurbishment — forging closer relationships between manufacturer and consumers); and reconfigured value chains (which are shorter, smaller, more localized, and more collaborative).

Much of the emphasis on AM’s effect on sustainability has focused on reduced energy and material consumption. But in reality, a true understanding of AM’s effect on sustainability needs to be somewhat more comprehensive, and assess how AM enables more sustainable models of production and consumption.

Looking at ways in which AM can enable more sustainable methods of production and consumption from a product lifecycle perspective, there are four key areas in which AM enables environmental sustainability benefits: product and process redesign; material input processing; make-to-order component and product manufacturing; and closing the loop (basically recovering and reusing AM materials, promoting the manufacture of parts when needed thereby reducing need for wasteful inventories etc).

Quite obviously, AM has a key role to play in a move to more environmentally sustainable industrial systems with its effect on consumption and production, but it also promotes the opportunity for manufacturers to assess the sagacity of alternative business models, the move to direct digital manufacturing will mean that digital designs will be kept on file, and can be reproduced as spare parts for repair and remanufacturing which will mean product life extension and incentivize product-service business models. Such shifts would affect the distribution of manufacturing and begin to reconfigure value chains, as does the ability of AM to reduce the need for sub-components and assemblies, which also simplifies supply chains.

AM Post Processing

It is important when looking at the use of AM as a production technology to analyse all the steps involved form product design to final end-use product or component. It is also vital when looking to promote environmentally sustainable industrial systems to take this holistic view as well, and here at Additive Manufacturing Technologies, we have an obvious and distinct focus on the post-processing stage for AM.

Many manufacturers underestimate the post-processing requirements when using AM, and therefore it is often the Achilles heel of the process and can be a huge barrier to the uptake of AM as a production tool. What many manufacturers are unaware of is that when using AM production applications, post-processing can be anything up to 60% of total cost per finished part. Surface finishing and other post-processing activities are often labour-intensive, and therefore cost- and time-consuming.

AMT is focussed on providing a cost- and time-effective portfolio of post-processing technologies that reduce the burden on manufacturers and increase the viability for manufacturers from across industry to use AM as a production tool.

However, we do this with a consistent and unflinching focus on the sustainability and safety of digital manufacturing systems.

It is my view that the post-processing puzzle needs to be addressed with an ecosystem approach to each individual AM production application — from end to end. This means joining the dots from product conception through to final product. Some post-processing issues can be reduced through diligent focus on design for AM (DfAM), but however good the design, it cannot negate the need for post-processing for all AM processes. At AMT we are only too aware of the irony that AM, the technology at the vanguard of the digital manufacturing revolution still requires almost pre-historic levels of manual intervention at the post processing stage, slowing the entire process chain down for production applications of AM, and potentially impacting on the geometric and functional integrity of finished parts.

This is why our solutions are digital and automated post-processing solutions that increase efficiency and reduce the overall time and costs of production with AM, specifically with polymer AM processes and thermoplastic materials.

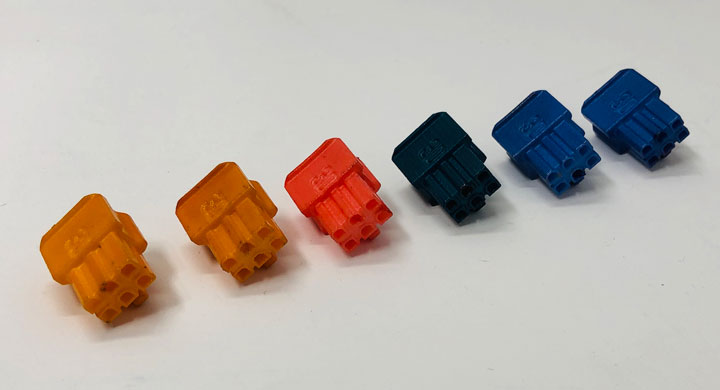

We are all aware that today there are a plethora of thermoplastic materials available for use on a variety of AM platforms, but powder-bed processes require significant powder handling and removal post build, and also invariably require infiltration operations, as well as finishing and colouring processes, particularly if aesthetics are important alongside the strength advantages that the powder bed fusion technologies offer.

Filament thermoplastic material processes, however sophisticated, always produce a stepping effect on built parts, which via conventional post-processing processes are hugely costly and time-consuming to eliminate.

AMT’s automated post-processing solution for smoothing high volumes of thermoplastic polymer parts to an injection moulded surface quality removes one of the biggest hurdles to the serial production process chain, and our PostPro3D range of hardware, which integrates new systems, software, and virtual services simply and efficiently removes the AM produced part from the machine, loads it onto a rack, and places it into the PostPro3D post-processing chamber. The user then selects the appropriate program and the process starts and runs for 90-120 minutes, after which the parts can be removed, inspected, and are fit for purpose.

AMT’s post-processing technology is a physiochemical process that involves converting a proprietary solvent into vapour under precisely controlled vacuum and temperature conditions. This precisely refines the surface of each part to ensure a perfectly smooth finish, equivalent to that of an injection moulded part.

Sustainability and Safety

AMT is all about the promotion of digital manufacturing systems, and recognizes the role that AM can have in promoting environmentally sustainable industrial processes moving forward. We embed sustainability across our entire operations both in terms of ethos, resources, and commercial offerings.

With this in mind, our fundamental focus was on enhancing the role of AM in such a sustainable system by producing a post-processing technology that was entirely safe and sustainable.

We have four pillars of sustainability which we build all of our core technologies from, no waste, better chemistries, less energy, less labour and consumables (See Table 1)

Table 1

|

|

NO WASTE |

No waste water effluent. Chemicals handled in a closed-loop zero-waste system. Compliant with local and international regulations. |

|

|

BETTER CHEMISTRIES |

NO CMR (carcinogenic, mutagenic, reprotoxic), category 1 chemicals NO Flammable or explosive chemicals All chemicals are REACH regulated |

|

|

LESS ENERGY |

Energy saving devices and shutdown functionality in every machine |

|

|

LESS LABOUR AND CONSUMABLES |

ROI justified within 2 months of purchasing our systems. |

The chemicals used in the AMT smoothing process are a proprietary mix of organic solvents developed by the University of Sheffield that are non-flammable and non-explosive. In fact, the chemicals have been carefully developed to be precursors and metabolites of those already used in the medical industry in FDA approved medical grade medicines thus minimising any potential issues with regard to human contact and environmental issues.

The chemicals are inserted into the PostPro3D machine by way of a cartridge, and are used in a completely closed system, which means there is no chance of contact directly with the user. Subsequent to completion of the process parts are completely free from chemical residues, and indeed post-processed parts are certified and biocompatible for medical device use under ISO 10993, and also have been tested to show they have no cytotoxic effect.

Our approach is testament to the fact that we have systems running with multiple blue chip OEMs across the globe including heavily regulated environmental jurisdictions such as California, USA.

As the PostPro3D is a closed loop system, there is also no waste stream for operators to dispose of. The machines require periodic maintenance by qualified AMT technicians, during which recycled consumables and carbon filters are collected and changed. We are the only post-processing ecosystem in the world to not have any waste streams from our products or require the use of water.

Additional safety features include multiple system redundancy and failsafe procedures with remote alarm transmission via internet connection, and 24/7 automatic remote monitoring of machine through the 3G cellular network.

The PostPro3D® is a CE and UL listed machine with file number - E500100, and with zero waste and optimized power consumption is a truly environmentally sustainable automatic post-processing solution that advances the use of AM in an advanced digital manufacturing system.

Summary

AMT is proud to be working at the vanguard of the digital manufacturing revolution, which offers huge opportunities for the development of environmentally sustainable and safe manufacturing systems. AM is obviously a key technology that would be included in any digital manufacturing scenario, but conventional post-processing technologies and techniques have negative implications for the use of AM for production applications, filing in terms of sustainability, cost, and timeliness.

AMT’s post-processing solution address all these drawbacks, and fits with our mission to work towards developing whole process chains that will enable manufacturers to transition to AM for an increasing number of production applications. This demands the development of more capable and connected systems, while simplifying the overall process to provide economically viable, automated solutions.

About Joseph Crabtree

Joseph Crabtree is the founder and has been the CEO of Additive Manufacturing Technologies since 2017. AMT is based in the UK, with global reach through facilities in the US and mainland Europe, as well as collaborative partnerships across the world. The company is currently emerging out of semi-stealth mode and into full production. AMT’s technology is developed at the intersection of material science, chemistry, hardware engineering, robotics and machine learning. The vision is to deliver safe, sustainable and economically favourable industrialised additive manufacturing solutions that offer a real and viable alternative to traditional manufacturing.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product