The requirement for reliability and precision is especially the case when looking at space/earth imaging devices, which must be rugged, produce exceptional results, while at the same time being competitively priced.

Building Optical Assemblies for Commercial Space Applications — Key Supplier Selection Criteria

Building Optical Assemblies for Commercial Space Applications — Key Supplier Selection Criteria

Joe Salemi, OEM Sales Manager Optical Components Group | Zygo Corporation

It is often easy to ignore the fundamental role that technology plays in our everyday lives.

Consider the ability to analyze changes to the Earth’s surface, daily. Consider the possibility of ubiquitous internet access even in remote parts of the world. Consider satellite navigation systems in almost every new road vehicle. All these and thousands of other activities that are driven by the need to monitor what is happening in the world every minute of every day are only possible because of commercial space projects, and the technology used in such space craft must marry reliability with utmost precision. It is not easy to go fix something when it breaks in space!

The requirement for reliability and precision is especially the case when looking at space/earth imaging devices, which must be rugged, produce exceptional results, while at the same time being competitively priced. Within the context of the overall commercial space industry sector (which Morgan Stanley estimate will be worth $1.1 trillion dollars in 2040 upon the introduction of new earth observation constellations, internet delivery applications, and other monitoring fleets), there is projected demand for hundreds if not thousands of space-borne optical assemblies.

These assemblies are likely to range in cost from $15K to $500K depending upon their end-use and complexity, such capital expenditure requiring the engagement of a highly skilled and experienced optics and optical assembly provider to ensure required functionality in mission critical applications.

ABOUT YOUR OPTICAL ASSEMBLY

Before moving to a shortlist of suppliers for your precision optical assembly, there are some fundamental considerations that need to be addressed.

First and foremost — and common to all commercial space applications — the optical assembly designed and manufactured must be able to withstand the enormous G-forces and vibration associated with rocket launches. It is of no use if your design is functional but too delicate to withstand such rigours. Here it is not just design for manufacture (DfM) that must be considered, but Design for Take Off (DfTO)!!

Second, will your optical assemblies be required to operate in a vacuum? If so, outgassing must be kept to a minimum, which dictates the ultimate choice of materials, coatings, and adhesives used. Manufacturing optical assemblies also requires a detailed assessment of the fabrication procedures employed, as it is vital that stress and burr-free parts are produced, and approved cutting fluids, and cleaning methods are employed Finally, optical assemblies for us in a vacuum must be assembled in cleanroom facilities, and packaged in a way that retains their integrity and cleanliness.

Third, it needs to be considered at design stage that optical assemblies for space applications must be able to withstand temperature ranges from -30 - +70 degrees C. Once again this will influence material choice and use of adhesives, coatings, etc…, all of which operate differently under temperature extremes. Designs need to be athermal while at the same time performing optimally and adhering to cost sensitivities.

Finally, it is vital that the manufacturability of a design is considered from the get go. Can it be reproduced at a reasonable volume, and is there a process that can scale it to higher volumes at a competitive price as well?

Editors Recommendation "Rebuilding Components With Reverse Engineering"

SUPPLIER SELECTION CRITERIA

With all such considerations in play, it is vital that your chosen optical assembly supplier is seen as a partner, engaged at the earliest possible design stage to ensure the shortest and most cost-effective product development cycle. Your partner should be able to work as an extension of your existing engineering and product development teams when necessary, as well as a standalone resource.

What should you look for in your nominated optical assembly partner?

Well, first and foremost is heritage. Does your short-listed optical assembly expert have a long and distinguished pedigree working with commercial space applications? There is no substitute for experience!

Experience implies expertise, and it is vital that your chosen optical assembly partner can demonstrate expertise in production of ruggedized designs at commercially competitive process.

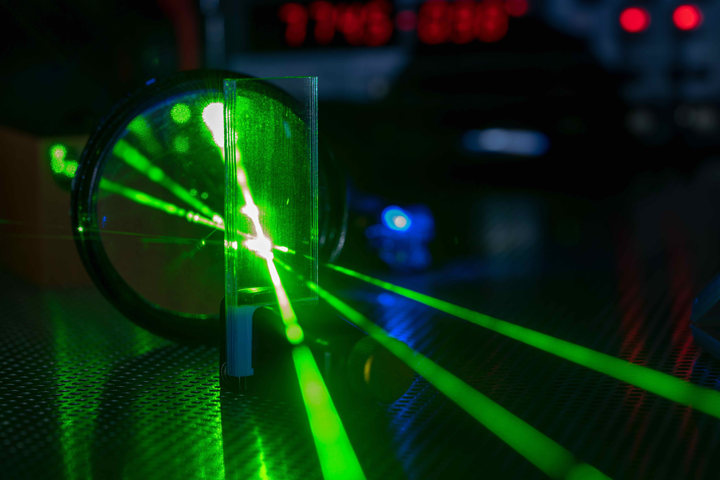

Also, of critical importance is that your optical assembly partner is vertically integrated, and is able to manufacture at volume. Ideally, your supplier should be able to manufacture optical components as well as assemblies, and it should also have at its fingertips an array of in-house metrology tools and methodologies that ensure the integrity of end-use optical systems.

Specifically, ask your supplier what experience they have in optical design and engineering, and the depth of understanding they have using refractive, reflective, catadioptric, and athermal designs.

With the emphasis on end-to end solutions, your optical assembly partner should ideally have the optical, mechanical, electrical, manufacturing, systems engineering, and program management capabilities (coupled with tier 1 volume optical assembly capabilities certified to ISO 9001 standards), to see your product through a successful development cycle.

When it comes to assembly, suppliers need to be able to demonstrate that they have the necessary cleanroom assembly areas in-house, and that they have all the necessary climate controls in place including particle, temperature, humidity, and ionization controls. In addition, ask if your chosen supplier has the ability to test optical assemblies under vacuum conditions.

Finally, drill down into the metrology credentials of your supplier. Quality control demands the use of best-in-class metrology tools, and an understanding of the use of such metrology tools to support an efficient and cost-effective production cycle.

SUMMARY

It is important that customers interrogate their short-listed precision optical assembly supplier, especially when manufacturing for exacting commercial space applications, to assess their ability to meet precision, reliability, and cost requirements. Mission critical optical assemblies as used in satellite-based optics demand attention to detail at every stage of the product development process. This requires that customer and supplier forge a true partnership relationship, and that the optical assembly supplier has the necessary pedigree, expertise, and experience in DfM and quality control to produce optimal results.

About ZYGO

ZYGO Corporation is owned by AMETEK, Inc. a leading global manufacturer of electronic instruments and electromechanical devices with annual sales of approximately $5 billion. ZYGO is a worldwide supplier of optical metrology instruments, high-precision optical components, and complex electro-optical systems, and Its products employ various optical phase and analysis techniques for measuring displacement, surface shape and texture, and film thickness. Electro-Optics and Optical Components businesses leverage ZYGO's expertise in optical design and assembly, and high-volume manufacturing of precision optical components and systems, for the medical/life sciences, defense and industrial markets.

If you like this article you may like "Quick Guide to Metal Additive Manufacturing for Industrial Components"

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product