B axis calibration is critical in 5-axis machine performance verification to maintain quality, but due to the design of the rotary heads, it was not possible to mount equipment to the centre of these axes to verify performance.

BOST Reduces Machine Set-up Time by 50% With Machine Calibration Solutions

BOST Reduces Machine Set-up Time by 50% With Machine Calibration Solutions

Case Study from | Renishaw

A well-established manufacturer of heavy and ultra-heavy lathes and heavy mills based in Asteasu, Gipuzkoa, Spain, BOST Machine Tools Company (BOST) was founded in 1972 as Talleres Bost, performing retrofitting services for lathes. Since 1987, BOST has been providing clients with comprehensive design, manufacturing, and installation services for newly built machine tools for general machining, such as turning, drilling, milling, and boring.

Background

BOST's capacity for innovation has been constant throughout its product range, transforming it into a technical company specialising in this sector since 1981. The BOST range of machines covers a wide variety of sectors including oil and gas, aerospace, defence, and railways. In addition, the company boasts 8,000 m2 of production facilities.

BOST's dynamic team continues to provide its clients with a highly flexible and personalised service. BOST insists that every machine undergoes a rigorous verification process that includes geometric precision, repeatability, and load tests before leaving the factory.

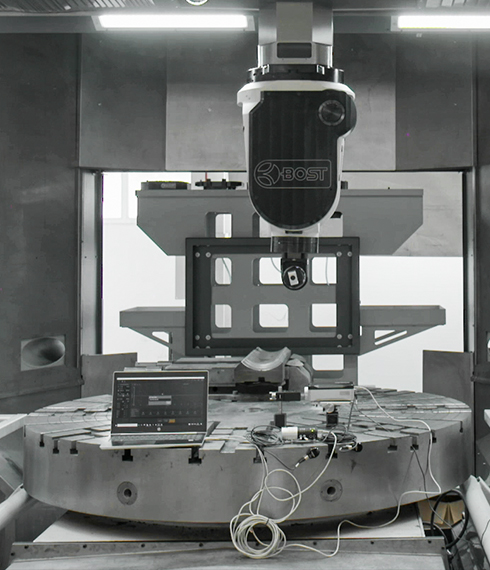

BOST's production facilities in Asteasu (Spain)

Challenge

With an increasingly demanding market, BOST was faced with the need to verify and improve the precision of rotary axes— the primary challenge being the calibration of rotary B axes. B axis calibration is critical in 5-axis machine performance verification to maintain quality, but due to the design of the rotary heads, it was not possible to mount equipment to the centre of these axes to verify performance.

BOST also wanted to improve the performance of C axes which were being measured using a pentaprism system. This method offered no measurement flexibility; a 360 degree test is limited to capturing 12 positions at 30 degree intervals.

Solution

Renishaw engineers demonstrated the XR20-W rotary axis calibrator on various machines at BOST. The XR20-W offered complete flexibility with test method set-up. Tests could be configured with capture intervals and measurement ranges to suit the requirements of the axis under test.

Renishaw's Off axis rotary software allowed the XR20-W to be mounted away from the centre of axis rotation, providing a simple solution for the calibration of rotary B axes.

This flexibility enabled BOST to see improvements in specification for both rotary B and C axes.

Results

In the search for the best possible solution, BOST turned to Renishaw having already adopted a number of Renishaw machine calibration solutions. The Renishaw XL-80 laser interferometer provides a stabilised laser source and environmental compensation, resulting in linear measurement accuracy within ±0.5 ppm, and reducing calibration time by up to 50%. BOST also uses the XL-80 to carry out precision checks on positioning performance of angular and straightness errors.

Machine calibration is verified using Renishaw's QC20-W ballbar system for circularity tests in XY, YZ and ZX planes. This has enabled BOST to produce high performance machines with traceable certification.

After consulting with Renishaw, BOST decided to purchase the XR20-W rotary axis calibrator, which offered the best 5-axis calibration solution for their requirements. When used in conjunction with the XL-80 laser interferometer it provides high accuracy of ±1 arc seconds, easy set-up, and fast data capture.

The XR20-W has the flexibility to be used for ‘on axis' or ‘off axis' applications using Renishaw's Off axis rotary software and CARTO software. Off axis measurement provides BOST with traceable calibration data.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product