While it’s common for many shops these days to cut gears on Multi-Tasking machines such as our INTEGREX i-450ST, fulfilling the customer’s request for tailored software to aid in programming proved a bit challenging to overcome.

Customer Challenge: Double Enveloping Worm Threading on a Multi-Tasking Machine

Case Study from | Mazak

Recently, a customer challenged Mazak to develop a programming and machining solution for producing a variety of Double Enveloping Worm Threads. The customer not only wanted the solution to be user-friendly and provide the ability to adjust the thread geometry based on inspection data (such as a roll test with a Master Worm Gear) but to also allow for the use of common off-the-shelf cutters.

Worm drives are designed in sets – namely, the worm and the worm gear or wheel. The thread geometry on these are parts is complex. However, when the mating worm gear geometry is a known, it is possible to calculate the thread toolpath trajectory. While it’s common for many shops these days to cut gears on Multi-Tasking machines such as our INTEGREX i-450ST, fulfilling the customer’s request for tailored software to aid in programming proved a bit challenging to overcome.

There are several benefits to gear machining on a Multi-Tasking machine. Doing so is cost-effective when it comes to producing a wide variety of gear types, and the machines allow for complete part processing from raw stock to finished part on a single platform. For gear machining, a Multi-Tasking machine offers the ability finish turn datums (i.e., bearing diameters) and gear teeth in the same setup, which gives more control between the gear pitch diameter and the mounting geometry. Additionally, Multi-Tasking machines simplify workholding and reduce tooling because they compress the machining cycle from multiple machines down to a single machine.

There are two process options to machine the Double Enveloping Worm Thread on the Multi-Tasking machine – turning and milling. Turning is a process option that depending on whether or not the machine’s longitude axis (in this case the Z-axis) can travel at the required speed. Much like chasing threads on a lathe, the Z-axis travel speed is based on the part rpm and the thread pitch. For multi-start threads, the Z-axis speed requirement increases even further.

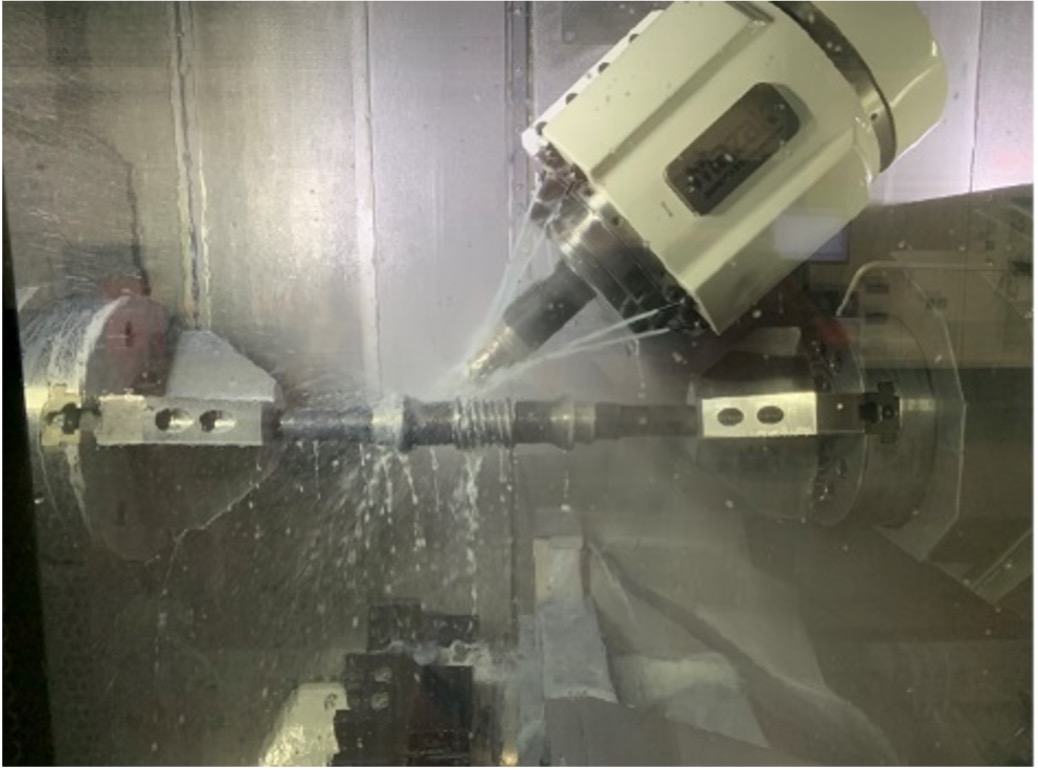

Milling is a process option that offers the ability to machine multi-start threads using a mill/turning technique. Essentially, the milling spindle delivers the cutting speed and the machines X, Y, Z, B and C axes provide the toolpath travel that replicates the rotation of the mating worm gear tooth.

For these operations, Mazak’s SMOOTH state-of-the-art control technology provides the high processing speed and ensures smooth toolpath contours resulting in superior finish and geometry. The technology also allows for unique machining operations such as Friction Stir Welding, Additive Manufacturing and Gear machining along with the execution of customized applications.

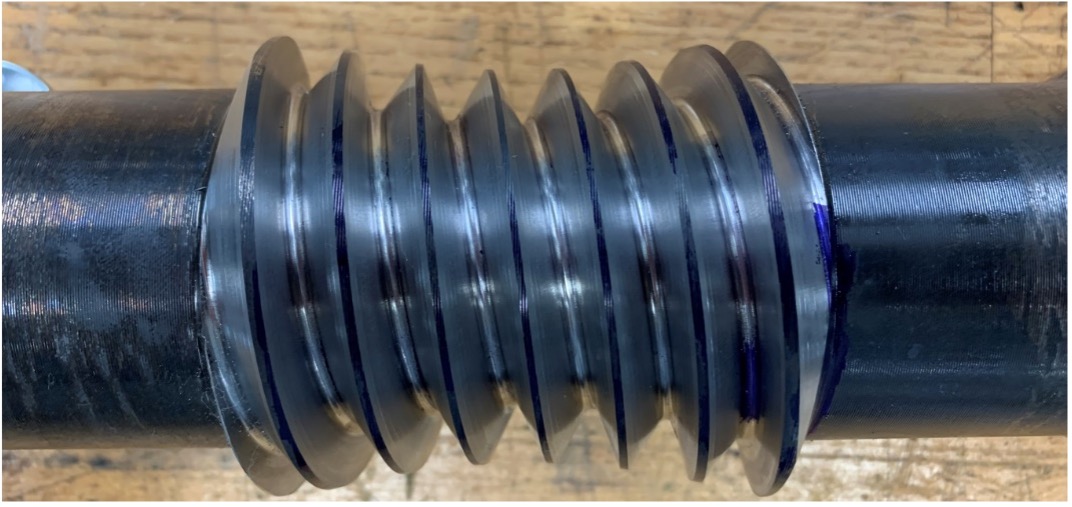

Custom applications are developed to run on the machine’s control. They create toolpaths for unique machining operations that would otherwise require a part model and a CAD/CAM system. An example is computing the toolpath to cut a Double Enveloping Worm Thread. This thread possesses an hourglass pitch silhouette, meaning as the worm thread rotates, the cutting tool follows the lead in the same manner as the mating worm gear tooth.

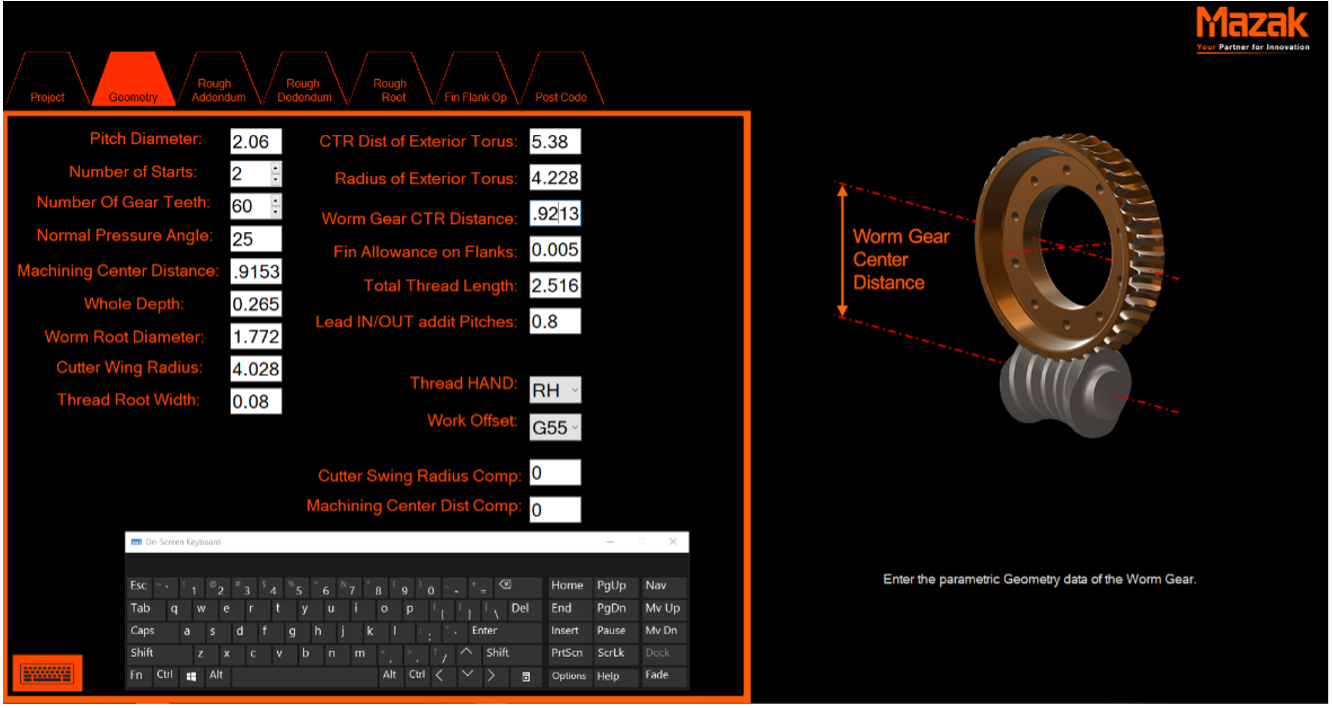

To accomplish this, the Mazak Applications Engineering department created a Double Enveloping Worm Thread Application that calculates the toolpath from graphical user interface data input. This Application runs on the MAZATROL SmoothAi control where the user simply enters the worm drive data such as number of worm gear teeth, number of thread-starts and pressure angle, along with cutting conditions.

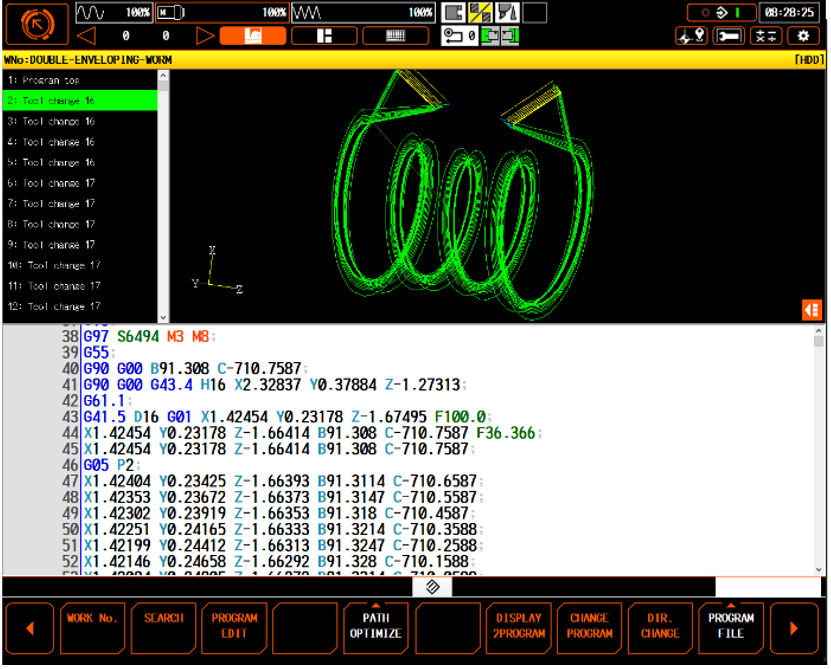

Upon completion of the data input, the G-code program is date-stamped and posted into the control’s hard drive. The customer can then review the posted G-code program toolpath on the machine control. Upon confirming the posted program, they can machine the thread.

Figure 2: Toolpath Review Figure 2: Toolpath Review |

Figure 3: Toolpath Simulations Figure 3: Toolpath Simulations |

Figure 4: Machining Between Spindles

Figure 4: Machining Between Spindles

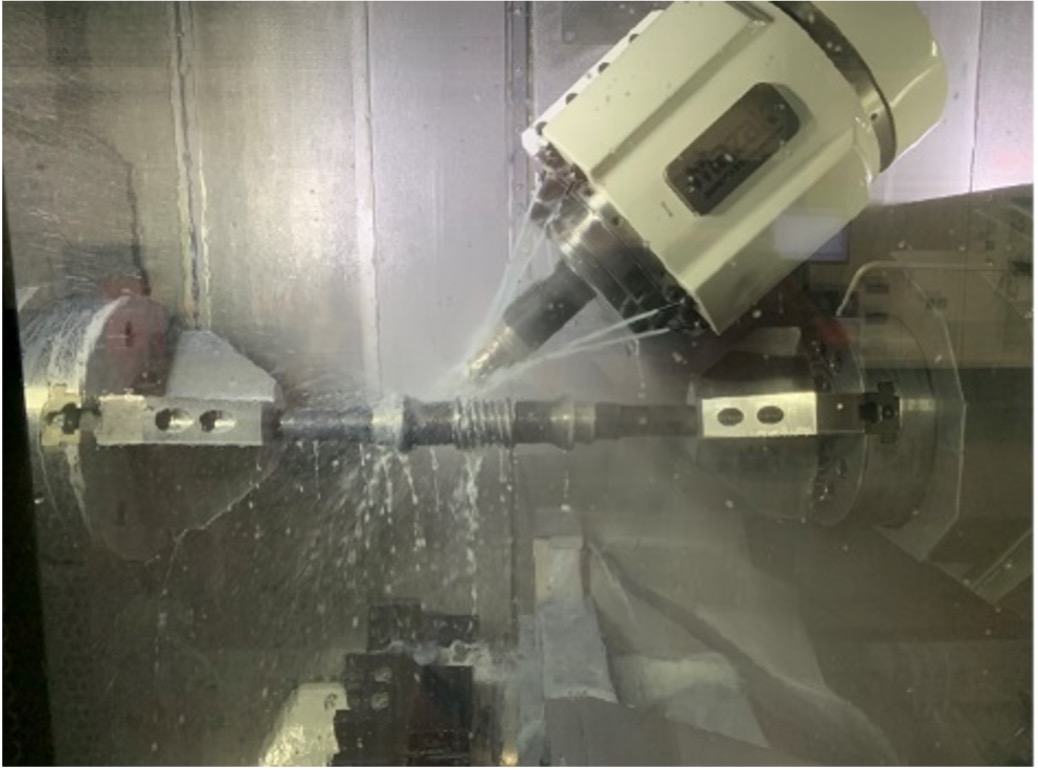

Figure 5: Finish Thread

Figure 5: Finish Thread

Besides Double Enveloping Worm Threads, Mazak Multi-Tasking Machines such as the INTEGREX i-450ST are capable of various other operations ranging from simple 2-axis turning to complex 5-axis simultaneous milling. The machine is truly an effective platform to cut parts traditionally produced on dedicated equipment, and Mazak continues to be the world leader in Multi-Tasking Machine Tool technology.

The versatility of Mazak’s INTEGREX i-450ST gives customers – like the one wishing to machine Double Enveloping Worm Threads – the flexibility to adjust to market demands. Many customers over the 30 plus years of the INTEGREX’s existence have put the machine to good use machining shafts, turbine blades, gears and so much more. Multi-Tasking Machines, like the INTEGREX, offer manufacturers more solutions and ways to boost their competitiveness in today’s world markets.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product