Good welders are hard to find and this problem will get worse in the future. But that's not the only reason why companies with welding departments would like to automate some of their jobs.

Getting Into Automated Welding Without Obstacles

Getting Into Automated Welding Without Obstacles

Daniel Kurr | TRUMPF

Good welders are hard to find and this problem will get worse in the future. But that's not the only reason why companies with welding departments would like to automate some of their jobs. Another reason is that when you weld for hours on end, your concentration wanes and quality can suffer considerably as a result. However, what keeps many potential buyers of welding robots and welding cells from making a purchase is the complexity of these machines. Especially for small series, the effort of programming is often not worth it. In addition, programming requires in-depth knowledge of welding technology, which in turn calls for a well-trained welder.

So some people ask themselves: Why isn't there an automated welding cell that is easy to program, has many parameters already integrated, and is in a lower price segment despite high quality demands?

Naturally, Andreas Zweifel immediately took notice when Patrick Kühne, customer service representative at TRUMPF Switzerland, told him on the phone about the TruArc Weld 1000 - an automated welding cell that combines all of these sought-after features. Still on the phone, the Managing Director of the family-business zweifel metall ag confirmed, "I want a machine like that at our company!"

Kühne has fond memories of the phone call: "I don't often sell machines directly over the phone," he laughs, "but I thought that a metalworking shop with 14 welding tables might well have a need for an automated solution that offers a price/performance ratio as good as that of the TruArc Weld 1000."

The TruArc Weld 1000 is the entry into simple welding for the company zweifel metall ag.

Andreas Zweifel: "I was already looking forward to the machine during the first conversation with Patrick Kühne, our customer consultant at TRUMPF Switzerland."

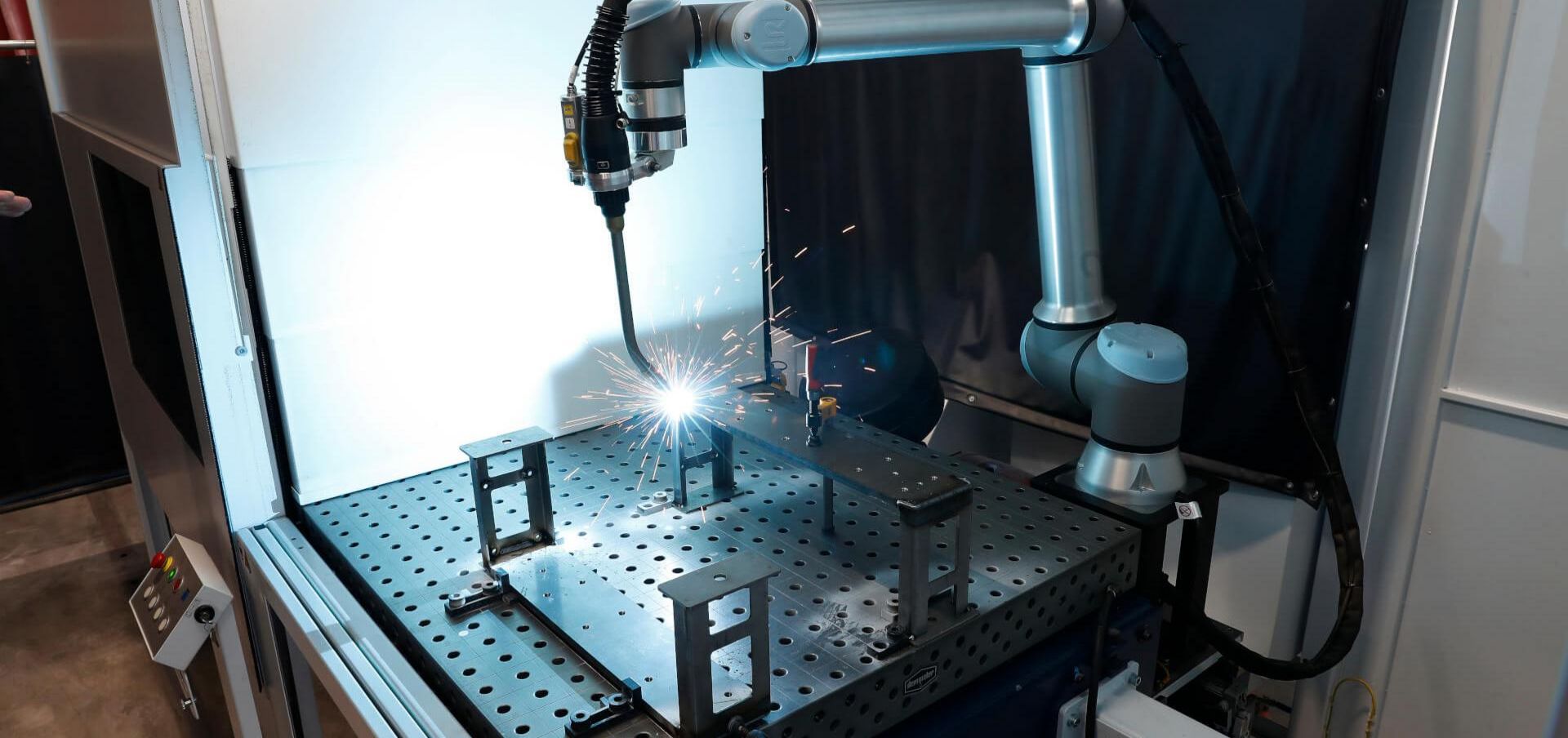

The automated welding cell that is easy to program, has many parameters already integrated and at the same time meets high quality standards: the TruArcWeld 1000 from TRUMPF.

SIMPLICITY THROUGHOUT

However, the welding cell stands out not only because of the relatively low investment costs. TRUMPF, known as a laser and machine tool manufacturer, has a number of welding machines in its portfolio - mind you, they are laser welding machines. The TruArc Weld 1000, however, is an arc welding machine; the welding source comes from the manufacturer Fronius. This welding cell is also equipped with a six-axis collaborative robot (cobot), a 3D welding table, a self-cleaning suction system, an enclosure with glare protection, LED lighting and safety equipment to TRUMPF standards.

"In general, care was taken with the TruArc Weld 1000 to maintain a customary high TRUMPF quality standard, combined with simplicity throughout," explains Patrick Kühne. This is evident, among other things, in the programming: It is a combination of an intuitive operating unit on the welding torch as well as simple programming directly on the robot controller for minimal programming times. In addition, the parameters for many welding programs are already entered.

ECONOMICALLY ATTRACTIVE EVEN WITH LOT SIZE OF 1

The goal in developing the welding cell was for users to be able to use the machine profitably even for the smallest of lot sizes. But it gets even better: The cell can often weld simple parts more economically than by hand, even with lot sizes of one. A reference example shows how a mild steel console with five welds is programmed and then welded by the robot in 329 seconds. This is 21% faster than the manual version, which took 415 seconds.

The fact that zweifel metall ag would also benefit from the robot's efficiency was therefore out of the question - and this became apparent very early on. Because even before the TruArc Weld 1000 was in the halls of zweifel metall ag, an inquiry came in, which they calculated as always for manual welding. But because the new welding cell was already installed in the hall when the order started, the parts were welded on the TruArc Weld 1000. The time saved - including programming and reworking - was more than 50 percent less than calculated in the original order! Another factor contributing to the time savings is that the welding cell can be converted into a 2-station operation thanks to a retractable partition wall, allowing the operator to set up parallel to production.

Even a lot size of 1 can be more profitable than with manual welding, because setting and especially "teaching" the robot arm is extremely simple. In the picture: Employee Blerim Limani at work on the TruArc Weld 1000.

Consistently high quality welds and fast set-up: Automated welding with the new welding cell brings considerable advantages for zweifel metall ag.

SET UP, READY, GO

Not only is programming the machine easy, so is setting it up. In addition to a QR code for a half-hour welding training course - after which you can already program your first welding operations - there is another QR code stuck to the machine wall. It is linked to a video for putting the machine into operation. Because here, too, simplicity is the basic idea that runs through everything. And so it should also be possible to set up and start up the machine yourself without a service engineer from TRUMPF, just with this instruction video.

Isn't TRUMPF asking too much of its customers? Patrick Kühne wanted to find out for himself. When the machine was to be delivered, Kühne told Andreas Zweifel, "I don't want to just be there to see if it works, but I'll set up the machine for you myself!" No sooner said than done. The former machine fitter was there in his "Übergwändli" (Swiss-German for cover-alls) on the day of delivery, and less than two hours later the machine was leveled, connected and ready for operation at the designated location. "There were no problems. My company really didn't promise too much," says Kühne happily.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product