Alex Anderson, Sales Engineer at Accumold systematically explores the crucial implications of vertical integration in micro molding projects.

The Critical Role of Risk Mitigation & Vertical Integration in Successful Micro Molding

The Critical Role of Risk Mitigation & Vertical Integration in Successful Micro Molding

Q&A with Alex Anderson, Sales Engineer | Accumold

In the area of micro molding, where precision and efficiency are critical, the role of vertical integration assumes fundamental importance. Accumold, a market-leading micro molding innovator has long championed the need for vertical integration to optimise micro molding outcomes, and in this exclusive Q&A article, Alex Anderson, Sales Engineer at Accumold systematically explores the crucial implications of vertical integration in micro molding projects. By elucidating the optimization of manufacturing processes, the stimulation of innovation, and the assurance of exceptional quality control, Alex imparts invaluable insights into how vertical integration has a transformative impact when undertaking often exacting micro molding projects for diverse clients across many industrial sectors.

How does Accumold approach risk mitigation in a micro molding project, and what specific strategies or protocols do you have in place?

The development of micro plastic parts and components involves multiple phases within a meticulously coordinated team. Design, materials, tooling, molding, validation, and assembly experts collaborate to achieve successful manufacturing at volume. In the micro manufacturing environment, where tolerances are measured in microns, unwavering attention to mitigating risks associated with non-adherence to these tight tolerances is crucial.

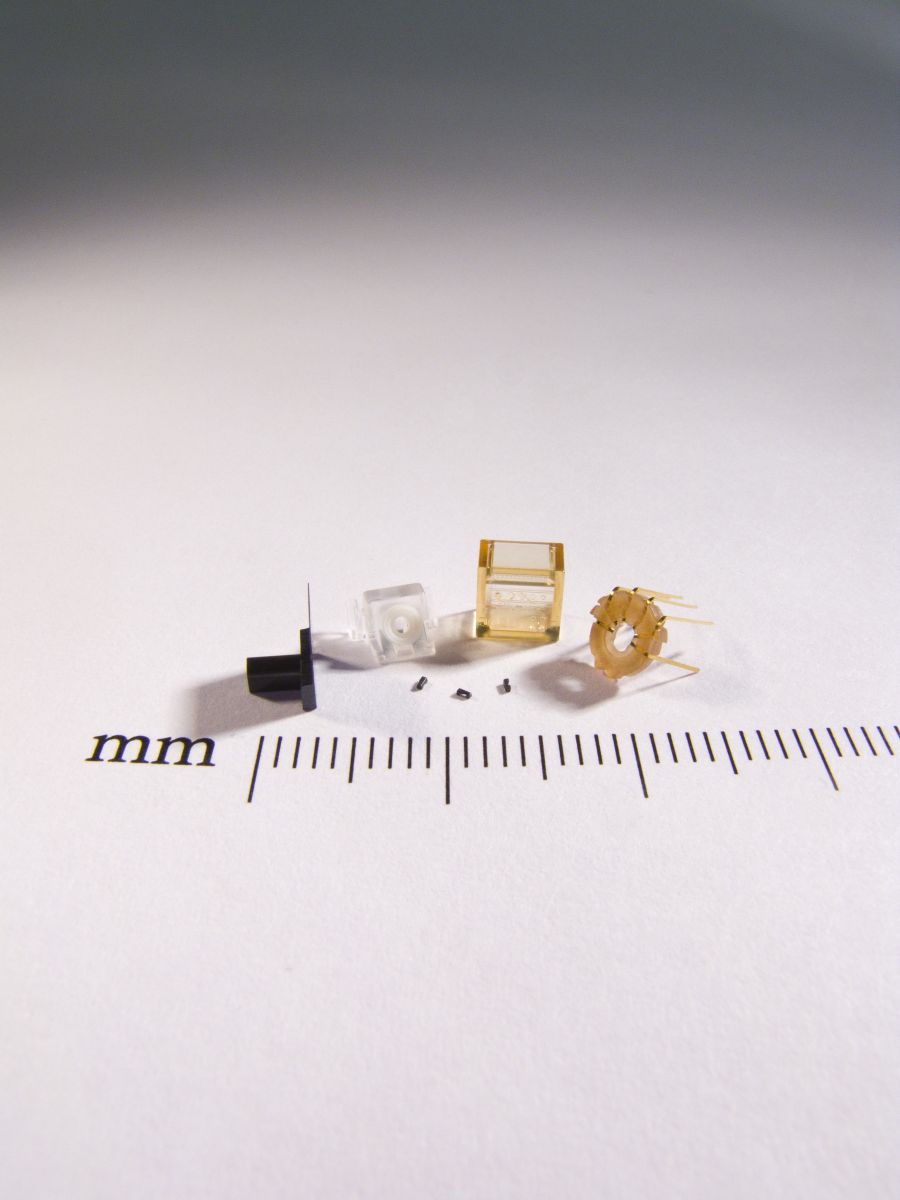

Micro molded parts, often weighing less than a gram and sometimes as light as less than 0.001 grams, often demand tolerances as low as 2 microns. For manufacturers unaccustomed to such levels of precision, the prospect of mass-producing parts with such dimensions and tolerances may seem insurmountable. However, micro molders like Accumold proficiently undertake this challenge on a daily basis, particularly in safety-critical applications where zero failure rates are imperative.

The paramount focus lies in meticulous attention to detail and process adherence. Micro molders must produce tiny parts with intricate features repeatably, attaining micron-level tolerances, all while maintaining cost-effectiveness and timely production. Hence, avoiding the need to revise designs, modify manufacturing processes, or recut expensive and time-consuming micro tools is of utmost importance. The guiding principle governing every activity throughout this complex process is to "get it right the first time."

In addition, at Accumold we lay great store in having the right blend of people with experience, drive, organization, and communication strengths. Also we promote open communication to weed out unforeseen challenges, and we up-front set expectations about the timing of a project, qualification, and production.

How does vertical integration within Accumold contribute to risk mitigation in in a micro molding project?

Well essentially, we own the whole process, and there is no one else to blame. Our customers like to know this, and the fact that if there is a problem, it can be resolved with a single phone call to the salesman.

Put simply, vertical integration is a strategic structure which means that we own the supply chain for the products we make. Fundamentally, this is considered to be important as it implies a certain and robust degree of control over operations (something under particular scrutiny today as companies assess the damage inflicted by the disruption caused by the coronavirus pandemic), an ability to offer lower prices, and also having increased market control.

Vertical integration conveys a likely advantage over competitors, reinforced by the ability to provide a lower-cost, higher quality product or service to customers. Independence from suppliers in the value chain is key, as this allows control over costs, and the unpredictability that occurs when relying on 3rd party supply. Vertical integration increases process efficiency, and this promotes greater time efficiency and shorter lead times.

What aspects of a micro molding project are vertically integrated at Accumold, and how does it help in mitigating risks related to supply chain dependencies or quality control?

Well the whole 9 yards — quoting, DFM, tooling production, production runs, quality control, and assembly. Having all of this under one roof mitigates risk because we all operate working together, there is no blame to be shifted.

Over-riding everything, and again playing to the need for true vertical integration is the required customer/supplier relationship that is at the heart of successful micro molding projects. A micro molder is not a job shop, but is instead a product development partner, and this requires a close and productive relationship with customers. Fundamentally, a micro molder should be able to influence the tricky area of Design for Micro Manufacturing (DfMM). Micro molders understand issues such as design for tolerance achievement, optimal gate locations, flash and mismatch, and can give advice on prioritising and limiting critical dimensions, and material selection for optimal outcomes.

The objective of all micro molding projects is the timely, cost-effective, repeatable manufacture of often complex and extremely accurate parts and components. The key is to get it right first time, and this can only be achieved by all teams in each stage of the product development process — from design to automated packaging — being engaged early in the process. A great looking design may be impossible to tool. A customer’s innovative concept may seem like the next big (but small) thing, but it would not mold successfully in the material chosen etc… etc….

You get the picture. Collaboration early in the design phase addresses such potential issues, and this is obviously streamlined and more efficient if all departments work and reside in the same facility, i.e. there is true vertical integration.

How does vertical integration enable you to have better control over critical components or materials and reduce the risk of delays or quality issues?

Because we quote and build our tools we have a better understanding of customer needs and how changes can impact our customers whether minor or major. Critical components often require the input of multiple groups within our organization. Just because the tooling team can build a critical tooling component a certain way doesn’t mean they should, especially if the manufacturability of the plastic part isn’t considered.

This emphasizes the importance of an integrated approach in the product development process, particularly concerning tooling and its impact on customer needs. By quoting and building our own tools, we gain a deeper understanding of customer requirements and the potential implications of any changes, be they minor or major. In the context of critical components, collaboration among various departments within the company becomes crucial. The tooling team's ability to construct a critical component in a particular manner does not automatically warrant its adoption, especially if the manufacturability of the plastic part is not taken into account.

The practice of quoting and building tools in-house allows Accumold to intimately comprehend the specific needs and expectations of our customers. This intimate understanding enables us to cater to customer requirements more effectively and respond swiftly to any modifications or enhancements requested during the development process. By maintaining a close relationship with the customer, we can offer a more tailored and satisfactory end product.

Recognizing the significance of critical components, we underscore the need for cooperation among various departments. Critical parts often involve complex considerations beyond tooling, such as design, materials, and manufacturing processes. Effective communication and collaboration between teams facilitate a holistic assessment of the component's viability, ensuring that all relevant perspectives are considered before making crucial decisions.

There are potential pitfalls if we solely rely on the tooling team's capabilities. While they may possess the technical expertise to construct a critical tooling component in a specific manner, overlooking the manufacturability of the associated plastic part can lead to complications during production. Therefore, it becomes imperative to involve manufacturing experts from the outset to assess the feasibility and efficiency of the proposed design and tooling approach.

Neglecting the manufacturability aspect can have adverse implications on both cost and time. Unforeseen challenges in the production process may result in delays and increased expense. Integrating manufacturability evaluations at an early stage allows us to identify and address potential issues, streamlining the manufacturing process and reducing overall costs.

By considering manufacturability concerns and involving various teams, Accumold fosters a culture of continuous improvement. Insights gained from past projects and collaborative efforts feed into the refinement of future processes and products, resulting in better outcomes and enhanced customer satisfaction over time.

How does vertical integration enable you to maintain control over critical processes, such as inspection, testing, or post-processing, and mitigate risks associated with outsourcing these activities?

Vertical integration in a micro molding scenario allows a company like Accumold to retain control over critical processes, such as inspection, testing, or post-processing, by internalizing these activities within their organization. By owning and managing these processes in-house, Accumold can implement standardized procedures, ensure strict quality control, and have better cost control. This approach also fosters streamlined communication and quicker decision-making, enabling continuous improvement and the ability to offer greater flexibility and customization to customers. Moreover, vertical integration mitigates risks associated with outsourcing, as it protects intellectual property, reduces reliance on external suppliers, enhances supply chain resilience, and provides faster turnaround times, all of which contribute to maintaining a competitive edge in the micro molding industry.

In what ways does vertical integration contribute to a more streamlined and efficient workflow, reducing potential risks arising from handoffs between different entities or external suppliers?

In a micro molding project, vertical integration plays a pivotal role in creating a more streamlined and efficient workflow, thereby reducing potential risks arising from handoffs between different entities or external suppliers. By encompassing critical processes like inspection, testing, and post-processing within their organization, companies like Accumold can maintain direct control over every stage of production. This seamless integration enables smoother communication, quicker decision-making, and the ability to address any issues promptly without relying on external entities. Consequently, there is a reduced likelihood of miscommunication, delays, or quality inconsistencies that may arise when multiple parties are involved. This level of control fosters a more cohesive and synchronized workflow, ultimately minimizing risks and ensuring a higher degree of quality and reliability in the micro molding process.

What questions do you ask of your customers which gives you the feedback you need to give an insight into the value placed upon your capabilities and expertise?

I ask customers what an ideal supplier looks like to them? Typically, they are caught off guard by this question but respond highlighting communication, lead time, or accountability. I also ask our customers what risks they see currently and in the future. This tell me what is most important to them during a project and allows me to prioritize accordingly. I in addition ask for an overview of their process once they receive their parts from us. Often times Accumold can provide additional value to our customers if we know where they are struggling. Finally, I ask what it is about their project they are worried about. This shows me their boundaries and what is likely to be unacceptable to them. It’s good to know what the hot points will be before you step on the land mine. For example, some customers are very worried about staying on schedule, and this tells me they probably want a weekly TEAMS meeting early in the week followed by a project summary late in the week. Some of my customers’ entire lives are their jobs, they are stressed out and will respond strongly to any negative feedback. In these cases its critical to have highlighted an issue early on otherwise it’s a surprise and nobody likes those.

About Alex Anderson

Alex Anderson is a Sales Engineer at Accumold. The company has grown to a 130,000 square foot fortified facility designed for assurance of supply, employs over 350 staff, and is a net exporter shipping all over the world every day from its Ankeny, IA, USA facility which runs 24 hours a day, 7 days a week.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product