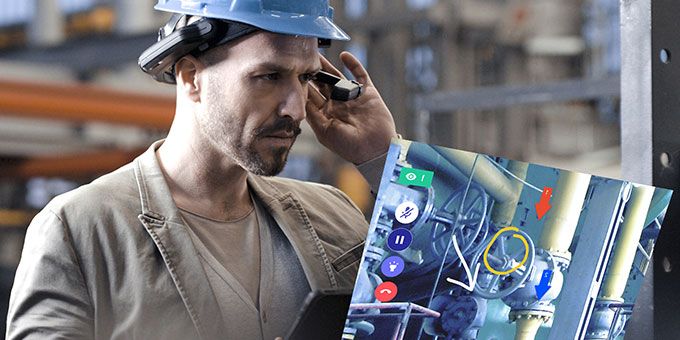

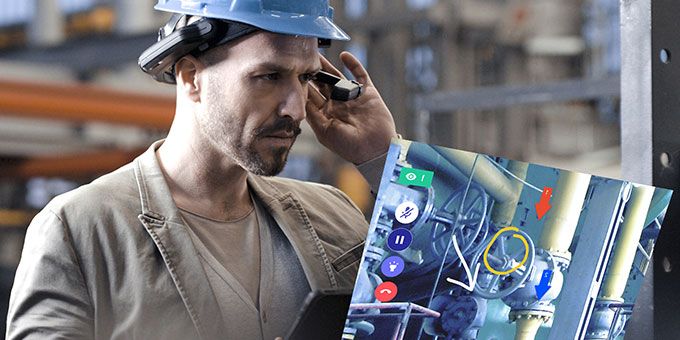

Visual remote assistance, or remote assistance in person, provides companies with a new way to organize their teams’ work. With an increased number of work-from-home methods, this new reality has helped companies increase their productivity by 30%.

Eckert & Ziegler Introduces Augmented Reality to Increase Customer Satisfaction by 30%

Eckert & Ziegler Introduces Augmented Reality to Increase Customer Satisfaction by 30%

Case Study from | Glartek

It is often difficult for companies to deliver services at anytime, anywhere. Experts with a high degree of know-how aren’t always available, and most of the time, their availability is not proportional to the needs of customers. Remote Assistance allows experts to work side-by-side with frontline workers and clients and ensure they provide assistance at any time.

Visual remote assistance, or remote assistance in person, provides companies with a new way to organize their teams’ work. With an increased number of work-from-home methods, this new reality has become more powerful over time and has helped companies increase their productivity by 30%. It also reduces travel by 25% and guarantees that every process is executed safely.

• Increase Productivity

• Reduce Travel time

• Executed Safely

ECKERT & ZIEGLER

Eckert & Ziegler is one of the world's largest providers of isotope technology for medical, scientific, and industrial use. The company, which has multiple subsidiaries, focuses on helping industrial leaders deal with radioactive substances and healthcare. Their goal is to lead the production, exchange, disposal, and storage of dangerous materials. Thus, it involves a high degree of know-how on dangerous procedures and the potential hazards of dealing with chemical elements.

By performing source tests, and providing supervisor and technical advice, as well as, emergency services, the company has been able to leave its mark on the industrial market and achieve a high degree of customer satisfaction.

CHALLENGE

Eckert & Ziegler is a service provider that has different subsidiaries. Isotrent, as one of these subsidiaries, has been challenged with high demand in regard to complex procedures, for only a small team of experts. Therefore, experienced resources are quite limited. Junior roles need to learn fast how to perform complex tasks and procedures, for both national and international customers.

As a result, the company is now faced with several new challenges:

1. Difficulty in ensuring correct support for customers

Customers are often confronted with unexpected problems and need support from the provider to reach a resolution.

2. Junior roles are difficult to train since senior experts are often busy The high-risk environment, in which the company works, demands highly qualified professionals. However, junior profiles are hard to train in a small team, since most experts are always busy.

3. Complex communication & training between Isotrent and its mother company Isotrent and its mother company are headquartered in two different countries. Consequently, communication, as well as new instructions, training, and other businesses between both companies are complex.

SOLUTION

In summary, the challenges faced by the company meant one thing: the expert team needed to be centralized and constantly available to help both customers and junior profiles. Additionally, training sessions for junior profiles must be straight to the point and the learning curve must be efficient.

Therefore, remote tools were the easiest way to address these challenges and the best way to carry out such demanding daily operations. The company invested in a Visual Remote Assistance that would avoid:

(1) experts having to travel;

(2) communicate through inefficient document-sharing tools.

The 5 steps solution is presented as follows:

1. Providing efficient Visual Remote Assistance tools to deploy in both field workers’ and clients' devices (mobile, tablet, PC, or smart glasses).

2. The expert team is centralized: Since experts now have more time available, the new reality becomes a centralized remote team able to help anyone at any time, using a remote assistance tool.

3. Remote training for junior profiles: Training sessions are more efficient because the Visual Remote Assistance solution helps experts provide accurate guidance during problem-solving.

4. A centralized management policy enables more control and visibility over operations. Time and costs are reduced, and decision-making is improved, optimizing the company’s continuous improvement strategy.

BENEFITS

Customers and junior roles embraced this change in remote work very well. Whereas, for the mother company-subsidiary communication, the changes remain slower. Resolution time and costs were dramatically reduced, and customer satisfaction was increased, by being able to answer their needs in real-time, which wasn’t possible before.

15% Productivity increase

Productivity increased by 15% due to (1) reduction of unplanned trips and (2) a more knowledgeable team. Eckert & Ziegler’s junior profiles started to learn faster, and experts are now able to answer more demands.

50% Problems reduced

Problems presented by customers or frontline workers are solved faster and with a high first-time fix rate for new problems.

30% Customer satisfaction increase

By having faster and high-quality problem resolution, customer service improved.

NEXT STEPS

1. Enable any interaction to be done remotely with the mother company (e.g., training, meetings, ...).

2. Solve facilities problems with the help of the German company to whom the building is rented.

3. Spread the tool to other suppliers, to improve interactions along the whole supply chain.

“With GlarAssist, we are finally able to keep our most experienced employees centralized, and consequently, our experts can solve more customers’ requests than before. Fortunately, both our junior workers and customers are learning how to perform operations they didn’t know before, which improved our operational efficiency and results.” Dr. Radek Řezáč, Operations Director

About Glartek

Glartek, founded in 2017, is a leader in Augmented Reality (AR) solutions for Manufacturing and Asset Intensive Industries and our mission is to increase the efficiency and safety of operational processes. Our software solutions combine the AR and Internet of Things domains to bring visibility, optimization, and reassurance to field operations. Glartek has offices in Lisbon and Leiria, Portugal, has very large customers such as EDP and Renault, and has raised over €1.5M in venture capital.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product