Enhancing production line efficiency while meeting the quality standards of small-scale components requires the accurate dispensing of highly viscous substances, such as sealants, glues, or solder pastes.

Fast Micro-Dispensing Actuators Benefit from the Piezoelectric Effect

Fast Micro-Dispensing Actuators Benefit from the Piezoelectric Effect

Article from | PI USA

Ultrafast Piezo Technology

Piezoelectric actuators boast swift reaction times and can achieve dynamic movements with displacements in the sub-nanometer range at frequencies reaching several kHz. Their lack of traditional moving parts and gears means they are maintenance-free, relying on the piezoelectric effect within their crystalline structure, devoid of any rotating or friction-causing elements. In terms of energy efficiency, piezo actuators stand out because they consume no electricity while idle. This allows for their use across diverse applications: for instance, in process technology, they enable rapid dosing cycles with finely tunable and precisely controllable travel ranges for dosing procedures.

Contactless Droplet Generation with PipeJet Dispensers

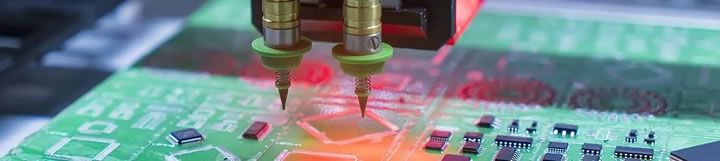

The direct displacement technique employed by PipeJet dispensers, driven by piezo technology, is notable for its distinctive approach, setting it apart from conventional piezo dosing methods. In this system, the fluid path consists of an elastic polymer tube with a precisely calibrated internal diameter. Piezo linear actuators are capable of compressing the tube via a piston, achieving constriction up to 100 times greater than that possible with, for example, ring actuators. This capability allows it to exert enough force to dose even highly viscous substances accurately. Additionally, this method is adept at handling fluids with particulate matter, such as paints or nanoparticle suspensions, dispensing them with precision in droplet form.

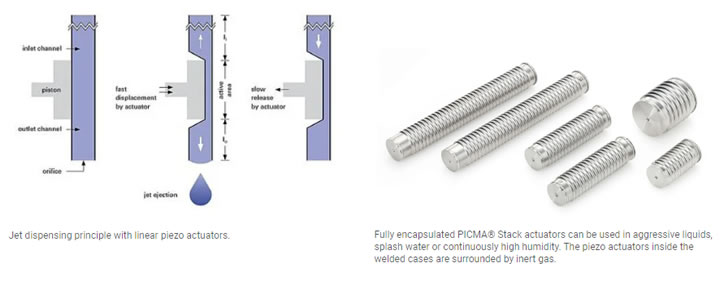

Highly Dynamic Application of PICMA® Multilayer Actuators

PICMA® multilayer piezo actuators excel in high-precision, dynamic dosing systems due to their rapid response characteristics and extreme reliability (these actuators were selected by NASA for the Mars Mission after surviving 100 billion test cycles without failures). The actuators' displacement rapidly follows its control voltage, propelling the actuator to its nominal displacement in about one third of the duration of its mechanical eigenfrequency. With appropriate drive electronics, these actuators can produce accelerations reaching several 1000 g’s. Dynamic tensile forces arise from the inertia of the attached masses and the actuators themselves, which necessitate mechanical preloads.

Losses and Self-Heating

The upper limit of the repetition rate for piezoelectric actuators is impacted by several factors. These include the resonant frequency of the system, the actuator's self-heating, the power output capabilities of the control electronics, and, in the case of closed-loop systems, the bandwidth of the control circuit. In scenarios where open-loop control is used and the operation occurs at the nominal voltage of the component (max displacement), the actuator's self-heating typically sets the repetition rate cap at several hundred Hertz.

The primary contributors to self-heating are the dielectric losses within the actuator, particularly when it operates below its first mechanical resonant frequency (recommended for maximum extension and lifetime). These losses are largely due to the actuator experiencing numerous reversible ferroelectric domain reorientations, leading to hysteresis in the dielectric response under higher electric fields. As the actuator is charged with dielectric reactive energy, this energy is temporarily stored. Upon discharging, most of this energy is returned to the amplifier. The energy represented by the hysteresis loop area is what ultimately converts into heat each cycle.

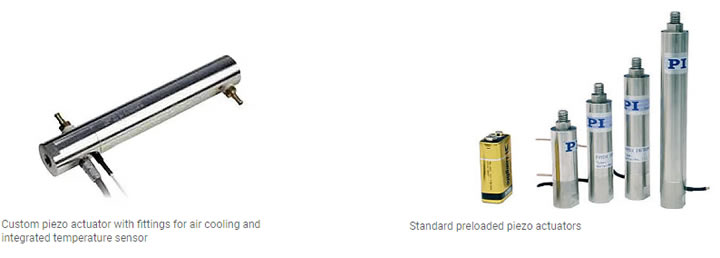

Experiments with PICMA® stack actuators, measuring 5x5x36mm³, reveal that under conditions of natural air convection, only about 20% of the heat generated dissipates through the end surfaces. The majority of the heat loss happens through the side surfaces. However, in their typical tightly sealed enclosures, natural air convection is minimal due to the restricted airflow. As a result, the application of electrically insulating thermal pastes or the implementation of forced cooling using compressed air are standard practices for cooling the lateral surfaces of these actuators.

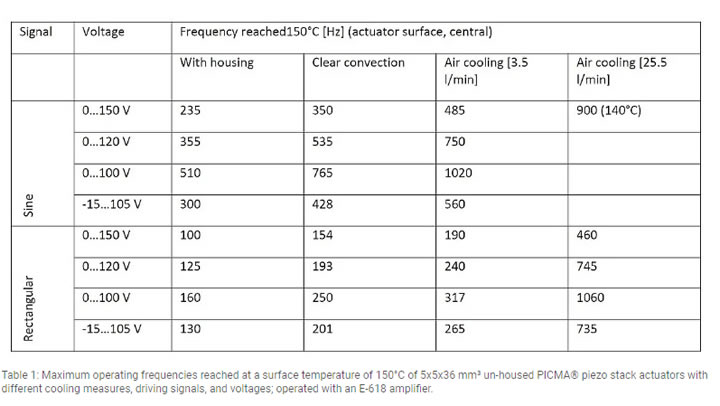

Experiments assessing the effects of various cooling strategies, types of control signals, and control voltage amplitudes were conducted on un-housed PICMA® stack actuators measuring 5x5x36mm³. Under the specific conditions outlined in table 1, the control frequency was incrementally raised until the actuator's surface temperature hit the critical threshold of 150°C, which is deemed the safe operating limit for standard PICMA® actuators. Beyond this point, the soldered joints may fail. For operations requiring temperatures up to 200°C, specialized solutions are available.

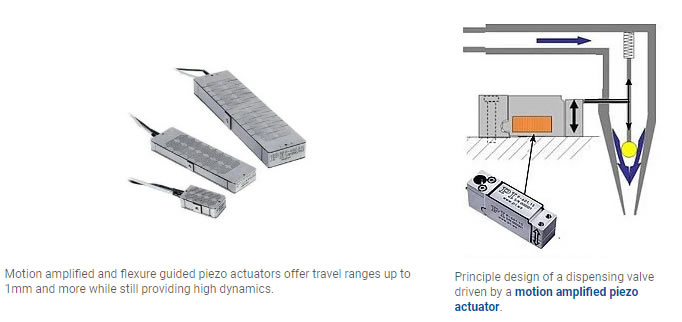

Motion Amplified Actuators

By implementing flexure-based motion amplifiers, significantly longer strokes of several hundred micrometers and even beyond 1 mm can be achieved. Here, a balance between force, maximum operating frequency and required stroke must be found together with the customer. The engineering team at PI USA has extensive experience in designing motion amplified piezo actuators for high-frequency dispensing applications.

Standard preloaded and motion amplified piezo actuators for displacements up to 1mm and basic principle of integration in a valve. For high-speed dispensing applications, custom designs that consider the specifics of the individual application (force, stroke, size, packaging, duty cycle, power amplifier, precision requirements) are required. The engineering team at PI USA has extensive experience in this field.

Heat Dissipation via the Piezoelectric Actuator

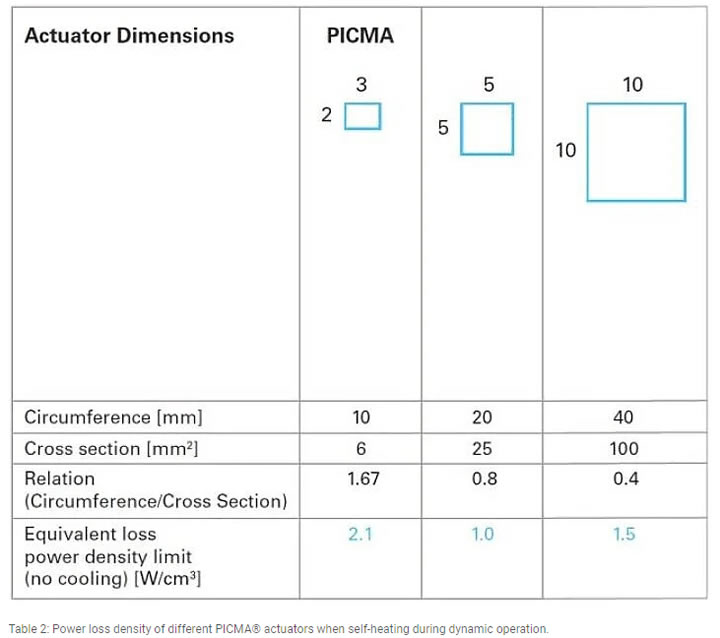

The effectiveness of heat dissipation in piezoelectric multilayer actuators is influenced not only by the individual cooling techniques but also by the actuator's design and the surface area available to release heat. Generally, larger actuators have a lower perimeter-to-cross-sectional area ratio, which leads to less efficient heat dispersion. For example, with 5x5x18 mm PICMA® actuators, one can expect that a power loss density of 1 W/cm³ — equating to an approximate self-heating of 10 to 20 K — can be managed without marked declines in performance. For smaller actuators with a cross-section under 3x3 mm, even a power loss density of 10 W/cm³ can be effectively managed using active cooling methods. The power loss densities for different sizes of PICMA® actuators are detailed in table 2.

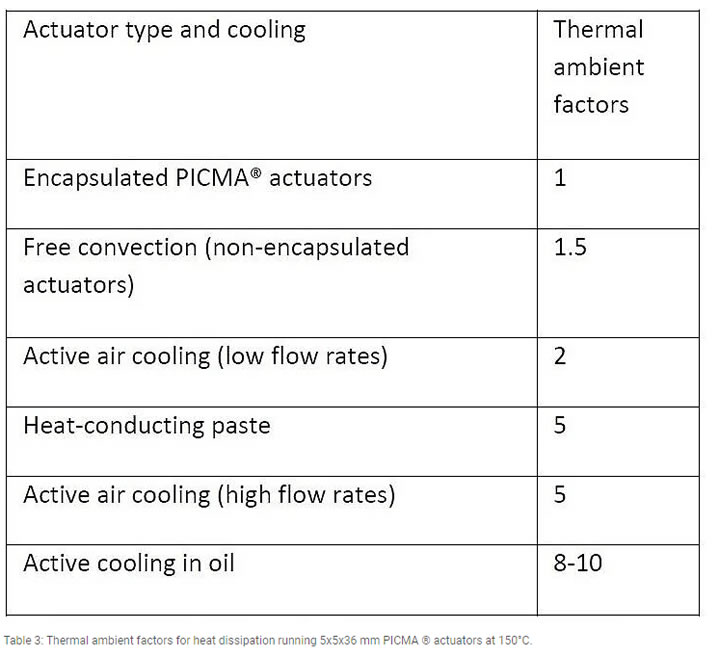

Table 3 presents the ambient thermal conditions conducive to optimal heat dissipation, using 5x5x36 mm PICMA® actuators as a reference. The data illustrates that actuators with encapsulation exhibit the least effective heat release. Conversely, the application of oil in active cooling systems results in the highest efficiency in heat dissipation from the actuators.

Which Actuators Are Suitable?

Table 3 demonstrates that active air cooling enables repetition frequencies approximately 4 to 5 times higher than those achievable in an enclosed environment without free convection. Furthermore, using liquid to cool the encapsulated PICMA® stack actuators can enhance the frequency up to a factor of 8 to 10. Air cooling supports frequencies up to 1,000 Hz, while liquid cooling has been shown to achieve frequencies as high as 3.3kHz at 100Vpp (35μm induced displacement). Additionally, this method maintains a self-heating level around 80°C, well below the critical 150°C threshold. The maximum frequency tested was limited by the small signal bandwidth of the E-617KDYN amplifier.

High repetition frequencies allow for extremely rapid cycling times with the actuators. Lifetime testing has confirmed that PICMA® stack actuators, sized 5x5x36 mm³ and operated with a 0…100 V sine wave, can sustain 10^10 cycles without issue. This durability was validated across samples of both non-encapsulated and encapsulated actuators with efficient heat dissipation. The combined use of encapsulated PICMA® stack actuators, active liquid cooling, and the E-617KDYN amplifier has proven capable of sustained operation at 3.3kHz at 35μm displacement under sine wave control in these studies.

High-Current PICMA® Multilayer Piezo Actuators

PICMA® piezo multilayer actuators with high-current electrodes for dynamic operation

PICMA® piezo multilayer actuators with high-current electrodes for dynamic operation

In dynamic displacement scenarios, such as in dosing and micro-dispensing applications using PICMA® actuators, the self-heating of the actuators, due to rapid high-frequency movements, needs to be considered in the design phase. Equally important are the current carrying capacity and temperature stability of the electrical contacts. When operating multilayer actuators dynamically, very fast voltage signals with rise times of 100-200μs are utilized. To efficiently charge and discharge a multilayer actuator in such dynamic conditions, a substantial amount of current must flow in a brief period. This intense current flow can significantly raise the temperature at the contact points of the actuators, potentially melting the soldering points in the actuator contacts. PICMA® piezo multilayer actuators, equipped with high-current electrodes, are particularly well-suited for these dynamic environments. The contact rails, shaped like a meander, are connected to the actuator via two large solder tracks, allowing peak currents of up to 20A during actuator control for rapid movements. The design also effectively accommodates the dynamic forces and displacements caused by the actuators.

Conclusion

PICMA® multilayer piezo actuators are ideally suited for use in high dynamics dispensing applications. With active cooling, highest repetition rates of 3.3kHz can be achieved – with a suitable power amplifier, even more. The high-current design of the electrical contacting bars ensures reliable operation of the piezo actuators, even at peak currents of up to 20A.

PI USA uses PICMA® piezo ceramics as the center piece of all high-speed, motion amplified custom dispensing actuators.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

PI USA (Physik Instrumente)

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1700 people worldwide. PI's customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors and aerospace.

Other Articles

High Precision Linear Motor Stages for Industrial Automation

More about PI USA (Physik Instrumente)

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product