BISON® TO SHOWCASE NAUTILAIR® COMBUSTION BLOWERS AND OTHER LEADING PRODUCTS AT AHR EXPO 2025

Nautilair® Combustion Blowers and other cutting-edge products empower engineers across diverse applications

KENT, OHIO - Bison® will display its latest innovations at the AHR Expo, February 10-12, 2025, at Orlando's Orange County Convention Center. Visitors to booth #3543 will experience firsthand Bison®'s robust and versatile product lines, including the renowned Nautilair® Combustion Blowers, Bison® Gearmotors, Lamb® Vacuum Motors, and Windjammer® Brushless Blowers.

For more than a century, Bison® has been at the forefront of fluid movement and power transmission technologies. The company's Nautilair® Combustion Blowers have revolutionized high-quality, power-dense systems in applications ranging from residential boilers to industrial kilns.

Nautilair® stands out in the combustion market with its unique features:

- Unmatched power density

- Sealed fan housing for direct burner mounting

- Optimized air-gas mixture for high-efficiency, low-emission combustion

- Brushless design offering variable speed profiles and extended lifespan

Available in sizes from 7.6 to 14 inches with various voltage inputs, Nautilair® outperforms competitors in both versatility and power, supporting boilers rated from 100 kW / 340 BTUs per hour up to 1,758 kW / 6M BTUs per hour.

While it has long been the go-to solution for traditional heating applications, engineers are continually discovering its potential in emerging fields such as radon mitigation, vapor intrusion mitigation, fume evacuation, and medical equipment.

Bison®'s expertise extends beyond Nautilair®, encompassing:

- Bison® Gear Motors include gearmotors, motors, and reducers for a wide range of applications

- Lamb® Vacuum Motors for air quality, central vacuum systems and more

- Windjammer® Brushless Blowers for diverse vacuum and pressure applications

- Prestolite Motors include PMDC & Wound Field DC Motors for industrial and commercial uses

- ROTRON® Regenerative Blowers for industrial, environmental and chemical processing applications

- ROTRON® Transportation includes brushless sealless pumps and DC motors for heavy-duty vehicles

Also at the booth, Bison® will showcase a compelling application featuring OBAR Systems, Inc., a leader in vapor intrusion (VI) mitigation solutions. OBAR has successfully integrated Bison®'s Nautilair® 7.6", 8.9", and 12.3" Combustion Blowers into their GBR series of VI mitigation systems. These systems create a vacuum under building slabs to safely remove harmful vapor-forming chemicals, protecting occupants from potential health hazards.

Attendees visiting Bison®'s booth #3543 can learn how this collaboration has resulted in cost-effective, compact, and highly efficient VI mitigation solutions that have become the industry standard. The case study will highlight how OBAR's products, utilizing Bison®'s Nautilair® blowers, have exceeded life expectancy by up to three times in demanding applications.

Visit Bison® at AHR Expo 2025 to explore how the innovative solutions can elevate your next project.

To learn more about Bison®'s products, visit BisonAMETEK.com.

ABOUT Bison®

For more than 100 years, Bison® has helped customers differentiate their products by developing robust, flexible and durable motors, blowers, and pumps under the brand names - Bison® Gearmotors, Lamb® Vacuum Motors, Nautilair® Combustion Blowers, Prestolite Motors Brushed DC Motors, ROTRON® Regenerative Blowers, ROTRON® Transportation Pumps and Motors and Windjammer® Brushless Blowers.

Bison® engineers thrive on technical challenges and provide customers with collaborative, customizable and optimized fluid-moving, fractional and integral horsepower solutions.

Bison® has worldwide sales representative support, research facilities and manufacturing facilities in North America and Asia. The company is headquartered in Kent, Ohio.

Bison® is a business of AMETEK®, Inc. - a leading global provider of industrial technology solutions serving a diverse set of attractive niche markets with annual sales over $7.0 billion.

Featured Product

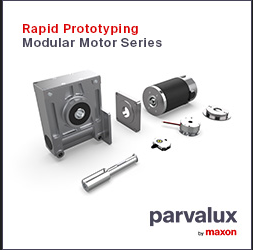

Rapid Prototyping with the Modular Motor Series

Quick to configure. Quick to build. Quick to deliver. Parvalux understands the importance of getting product in the hands of customers quickly and efficiently. The Modular Range does just that allowing customers to configure their own solution, selecting motor and gearbox, adding encoders and brakes to create a solution perfectly suited for their specific applications such as conveyor belt systems, picking systems, parcel sorting equipment, pallet shuttles and automated storage and retrieval systems (ASRS). Read our modular range guide for specifics.