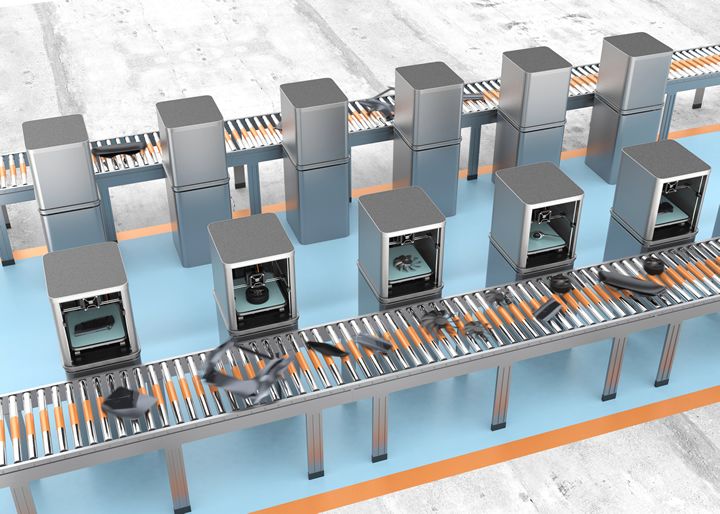

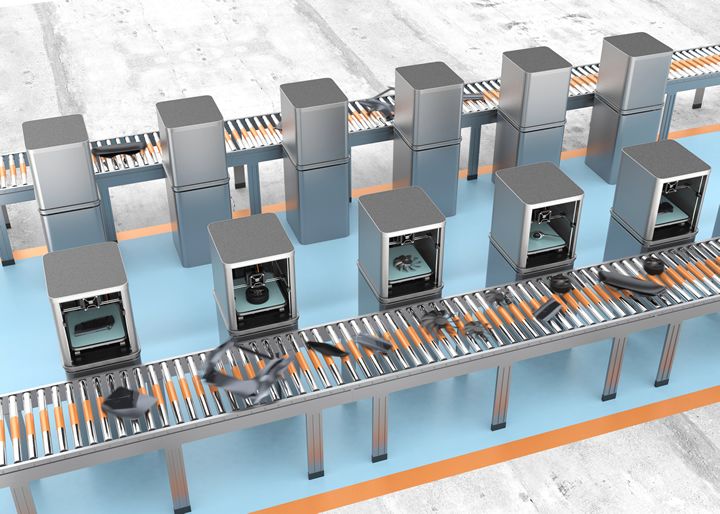

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

Thomas Sorovetz, Event Advisor for RAPID & David Haydon, Sales Engineer | Blue Fire Manufacturing LLC

In the early days of additive manufacturing (AM), the technology was anything but seamless. Machines were few and far between, and materials were brittle. Early stereolithography parts were so fragile that, when dropped, they would shatter into dozens of pieces. Other methods, such as laminated object manufacturing (LOM), carried inherited risks and required full-time monitoring. Since operating the hardware relied heavily on insider knowledge, training was also a challenge.

Fast forward to today, and AM has matured into a practical tool for manufacturers of every scale. Materials are stronger and more varied, machines are more intuitive, and automation has significantly reduced labor demands. With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

Practical Applications of AM

Many small and medium-sized shops are already putting industrial 3D printing to work. AM is reshaping how these companies prototype, validate designs, and maintain quality, allowing them to identify issues early on and sidestep costly delays in the production cycle.

Early-Stage Prototyping

Before committing to tooling, manufacturers need to make sure their design will work as intended. AM allows companies to build and analyze prototypes early in the development process, assessing how individual parts will function within an entire assembly.

Design Validation

As manufacturers move closer to production, accuracy becomes the priority. Discrepancies between computer-aided design (CAD) models and 2D drawings — especially in geometric dimensioning and tolerancing (GD&T) — can cause expensive mistakes. Industrial 3D printing offers a tangible way to validate CAD models, ensuring the final product aligns with the design intent. One client we worked with, for instance, discovered that a component they had designed would fail due to unexpected stress — something that was not apparent from the CAD model.

Inspection and Quality Control

Fixture and check gauges play an important role in quality control and dimension verification. However, traditional steel check fixtures are expensive and take a long time to fabricate. AM accelerates this process, providing a lightweight, cost-effective alternative that companies can produce and iterate on quickly. If a fixture is dropped or damaged, it can easily be reprinted, avoiding lengthy production delays.

Common Reservations Around AM Adoption

Despite the advantages of industrial 3D printing, many small and medium-sized manufacturers hesitate to adopt the technology due to concerns about cost, risk, and implementation challenges.

Limited Capital for Experimentation

Purchasing the wrong AM system could result in an expensive “boat anchor” — a machine that sits unused because it doesn’t meet the company’s needs. Unlike larger corporations, small and mid-sized shops don’t have the budget for costly trial and error. And with so many solutions available, choosing the right one can be overwhelming. One way to ease into the technology is to start small. Lower-cost desktop models offer a hands-on way to test applications, work out potential challenges, and gain confidence before committing to a larger industrial system.

Knowledge Gaps and Training

Historically, AM required specialized expertise, making adoption difficult for companies that lacked dedicated in-house knowledge. However, the contemporary workforce is far more familiar with the technology. Many students begin experimenting with 3D printing as early as grade school. By the time they graduate college or university and enter the industry, they already have a practical understanding of how AM fits into different manufacturing processes.

It’s also become easier to cross-train existing employees. With improved software, user-friendly hardware, and more educational resources available, manufacturers can integrate industrial 3D printing into their workflows without the steep learning curves of the past.

The Cost of Falling Behind

For small and mid-size manufacturers, AM has evolved into a powerful resource for boosting agility, reducing costs, and driving innovation. The playing field has shifted. Not long ago, industrial 3D printing was largely limited to major corporations with deep pockets and extensive resources. Today, it’s a viable option for companies of all sizes.

Take the aerospace industry, for example. Earlier this month, Firefly, a Texas-based aerospace start-up, made headlines when its Blue Ghost lunar lander successfully touched down on the moon. The first commercial spacecraft to achieve this feat, the lunar module was powered by thrusters made with 3D-printed parts provided by Castheon. This kind of opportunity wasn’t even imaginable for small and medium-sized manufacturers a decade ago. Now, thanks to AM, companies can test designs, iterate quickly, and produce high-quality parts without the heavy upfront costs.

The flip side to all this is that smaller players who ignore AM risk falling behind. Competitors who adopt the technology will be able to move faster, reduce waste, cut costs, and, increasingly, unlock lighter, smarter materials that wouldn’t be accessible without additive technology. Those who hesitate could quickly find themselves outpaced.

Bringing AM Within Reach

Fortunately, manufacturers have a growing number of AM-related resources at their fingertips. Industry events like RAPID + TCT offer hands-on learning, access to experienced professionals, and real-world insight into what works — and what doesn’t. Networking events, such as those coordinated by SME and the Additive Manufacturing Users Group (AMUG), create opportunities to connect with those who have successfully integrated industrial 3D printing into their operations.

At the same time, the technology is becoming more accessible. AM is no longer a niche skill. Awareness has increased, and many engineers and technicians entering the workforce already have extensive experience with industrial 3D printing. Meanwhile, machines and materials have become more affordable and easier to implement.

Smaller shops don’t have to make this shift alone. Those who have been in AM for decades are eager to share their expertise and guide others. By staying engaged, asking questions, and learning from industry veterans, companies of all sizes can make smart, informed decisions that strengthen their competitive positioning and lay the groundwork for future growth.

David Haydon is a Sales Engineer at Blue Fire Manufacturing LLC, a full-service manufacturing company that offers engineering and design services, precision machining, prototype stamping, production stamping, and casting.

Thomas Sorovetz spent over 35 years working in automotive manufacturing before launching his own consulting practice. He is an event advisor for RAPID + TCT 2025, which will take place April 8 – 10 at Huntington Place in Detroit, Michigan.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product