Manufacturing and Automation - Articles, Stories & Interviews

How Industrial 3D Printing is Propelling Small and Mid-Sized Manufacturers Forward

With lower barriers to entry, small and mid-sized manufacturers have more opportunities than ever to integrate industrial 3D printing into their operations while avoiding the hurdles that once held them back.

Securing Intellectual Property in 3D Printing: A New Era of Protection

By decentralizing manufacturing and leveraging external service bureaus, companies can deliver products faster and tailor offerings. However, due to both its quick, cost-effective, and precise manufacturing process, 3D printing is a fine target for counterfeiting.

Pricing Optimization for SMB Manufacturers

Emphasizing value over price has to be the priority for smaller manufacturers with limited resources. Manufacturers in niche industries have unique insights into the specific needs and price sensitivities of their customers.

Will AI Take My Job in Manufacturing?

While employees have every right to be sceptical about AI, it’s important to note that integrating AI into existing workflows is actually in place to enhance productivity and remove the need for time-consuming manual tasks.

Stick with OEM Parts When Replacing Racking Components

Beams, uprights, braces and other elements of a pallet racking system often need to be replaced due to damage caused by forklift impacts or other causes. It’s important to replace the components with parts from the same manufacturer, and not from another source.

The Reshoring Revolution: Navigating New Policies For A Manufacturing Renaissance

As President Trump's second term unfolds, the manufacturing landscape in the United States is poised for a significant transformation. The administration's renewed focus on reshoring manufacturing operations presents both opportunities and challenges for industry leaders.

Penn Waste Inc. Minimizes Machine Downtime and Improves Efficiency

Penn Waste realized that it needed an advanced wireless solution combined with smart sensors that would deliver accurate, reliable and continuous real-time data for predictive maintenance.

Manufacturing and Automation - Featured Stories

How Product Catalog Management Supports Circular Supply Chains in Manufacturing

Most ERP and PLM systems track products only through production and sale, not reuse, refurbishment, or recycling. This fragmentation causes material loss, inefficient remanufacturing, slow reverse logistics, and compliance failures.

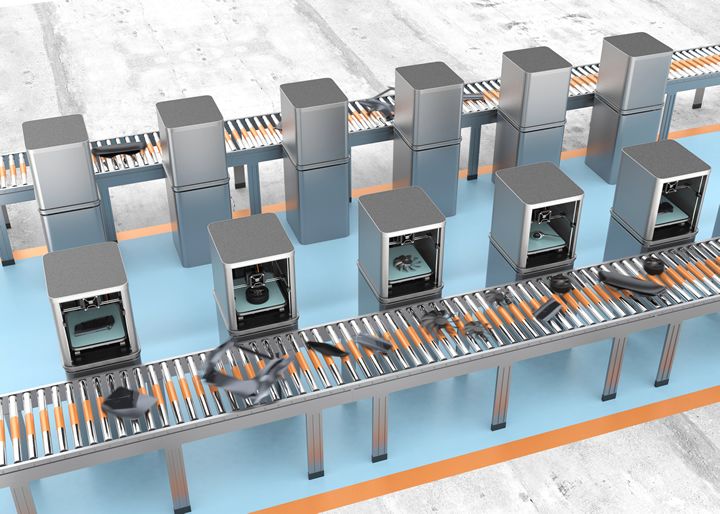

The Evolution of Mass Custom Manufacturing: Why the Industry Needs a High-Velocity Shift

.jpg)

HVMC is not just faster production but a fundamental reimagining of how custom manufacturing operates. By standardizing and automating processes without sacrificing the ability to tailor products to specific needs, HVMC has the potential to transform the landscape.

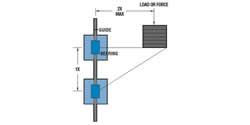

What is the 2:1 Ratio For Linear Plain Bearings?

The 2:1 Ratio represents the maximum allowable moment arm distance relative to bearing length without causing binding or motion restriction, ensuring optimal performance in plain linear bearings.

Manufacturing and Automation - News Headlines

Understanding the Benefits of Active PoE Switches

Article by Henry Martel, Field Application Engineer, Antaira Technologies

WireCo introduces Lazerlift: The New Generation of Rotation-resistant Hoist Ropes

WireCo introduces Lazerlift: The New Generation of Rotation-resistant Hoist Ropes

Trafag Highlights the 879x Hybrid Gas Density Monitor for Advanced Gas Monitoring

Combines Self-Acting Monitoring and Continuous Density Measurement for Enhanced Reliability and Leakage Detection

SupplyOne's Vendor Consolidation Services Drive Efficiency and Cost Savings

Optimized Supply Chains, Reduced Costs, and Improved Compliance for Manufacturers and Food Processors

Pfannenberg Combines Free and Active Cooling in DHS Hybrid Series

Maximize Cooling While Minimizing Energy Use and Reducing Carbon Emissions

Manufacturing and Automation - Featured Product

MOTION CONTROLLERS FOR MINIATURE DRIVES AND MICRODRIVES

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new Motion Controller is ideal for integration in equipment manufacturing and medical technology applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to approx. 100 W and is suitable for DC-motors with encoder, brushless drives or linear motors.

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.

.jpg)