"Smart Engineering" for building services and industry at Alexander Bürkle

In the more than 100 years since its foundation, Alexander Bürkle GmbH & Co. KG has always been reinventing itself, but always based on its established core competencies. The company, which employs around 800 people at 22 locations in southern Germany, is currently moving from being an electrical wholesaler to a service provider that offers customers in building technology and industry smart engineering support, thereby supporting them on their way to a digitalized future. Alexander Bürkle has developed an entire portfolio of "smart industry" services for its target industrial market.

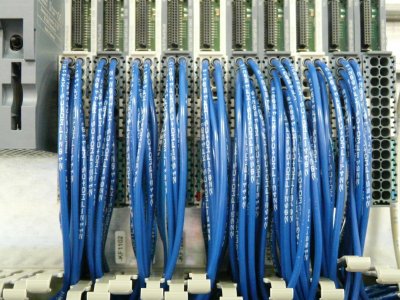

Figure 1 At Alexander Bürkle, wires are labelled automatically from Eplan.

The basis for these services is control cabinet engineering, which Alexander Bürkle offers for building services engineering (electrical distributors) as well as for industry. Initially, this department worked as a contract manufacturer for its customers. The business segment was then expanded in a targeted way to include semi-automated systems for wire assembly, labelling and metalworking, as well as smart services such as control cabinet optimization. This resulted in increasingly more companies taking advantage of Alexander Bürkle's engineering know-how. Control cabinet engineering therefore grew continuously.

The beginning with "Smart building" one and a half years ago

A good one and a half years ago, management decided to consistently expand the engineering services in this area and to show customers a way into Industry 4.0 using a new concept for the planning of electrical systems. Building services engineering was the first. Fabian Camek, Engineering Manager: "We replaced the ECAD software, migrating it to Eplan which offers the best opportunities for end-to-end data utilization - from the initial concept through to detailed planning and plant operation".

Figure 2 Fabian Camek, Head of Electrical Design at Alexander Bürkle GmbH & Co. KG (right), with Ruben Schemel, Head of Production Control Cabinet Construction and Production Planning

The benefits of building distributor design with EPLAN Cogineer and Preplanning tools can be described in one sentence: "While the designer - usually on site at the customer premises - configures the distributor and selects and assigns components via drag & drop, the ECAD system takes over the design work in the background", sites Camek. The basic planning work is therefore carried out automatically down to the fine detail. Labelling of wires and conductors - which are also automatically created later - is then already established as is the 3D structure of the control cabinet.

Second step: Control cabinets for Industry 4.0

In a second step, Alexander Bürkle transferred these principles to control cabinet engineering for industrial customers such as leading machine tool manufacturers. Here, too, the amount of engineering is increasing, so an important prerequisite is integrated planning and electrical design on the EPLAN Platform, which begins with EEC One (in future with EPLAN Cogineer). (Pre-)planning is carried out using EPLAN Preplanning, 3D control cabinet layout using EPLAN Pro Panel, and hydraulic and pneumatic control design using EPLAN Fluid.

EPLAN with all characteristic data and dimensions. Three colleagues in the electrical design department record new parts according to standardized guidelines, stored in a "Style Guide", and enter them into Alexander Bürkle's parts database.

It is effort that pays off for both Alexander Bürkle and the customer. Fabian Camek: "For us, this speeds up control cabinet design considerably because the parts are selected according to a system of options. We also make the data available to customers on request, and there is hardly a customer who doesn't appreciate this service".

Parts database as the basis for a "digital twin

It is therefore only logical that Alexander Bürkle also offers this service to customers in the industrial sector. Providing parts data according to the Style Guide standards is a project that is carried out separately from control cabinet design. The demand for the data is high. The reason for such demand is that for mechanical engineers and their customers, the data portrays "digital twins", i.e. the virtual image of a machine or system that can be updated to its real twin over an entire service life. Fabian Camek: "Because digital and real systems are permanently connected, they develop an object memory. Those who use and maintain the digital data save time and money because they can, for example, better plan system implementation and maintenance and always have all the necessary information at hand when servicing is required. This data is also very valuable when modernizing or converting a machine".

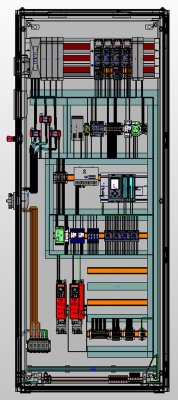

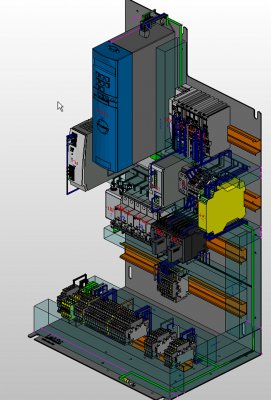

Figure 4 ... and a portrayal of a "digital twin". View from EPLAN Pro Panel

The advantages of end-to-end data utilization

When asked about the other advantages of integrated electrical design, Fabian Camek was able to come up with many aspects: "We now design organically, starting from the functions and structured according to modules and fields". Designers do not start with selecting a control cabinet size because its size automatically emerges from the functions, components and modules. Electrical designers use the Rittal range unless customers request otherwise. According to Fabian Camek, the improved workflow also means that designs are error-free right from the start. Furthermore: "Many specific tasks, such as selecting the wires for cable ducts or labelling equipment, are performed automatically. The data can even be used for seaworthy packaging. The dimensions of a seaworthy crate can be derived from EPLAN, as can the transport weight for the forwarder".

Figure 5 A typical product from Alexander Bürkle – a real mounting panel

Worldwide first use of the Terminal Server

The Terminal Server further improves data consistency and transparency. The EPLAN software was adapted to this technology, which enables a centralized infrastructure. Required data such as 3D views of control cabinets, circuit diagrams, etc. are provided independent of location, e.g. on a laptop or tablet. Fabian Camek: "We are the first in the world to use this tool and have also used it to link up with electrical designers in the Frankfurt branch. We design and build the control cabinets there for the US market according to UL/ ANSI and, by using the Terminal Server, can access a shared data pool from both locations".

On track to move from being a manufacturing service provider to a systems house

In view of these benefits and the high demand for advanced engineering services, it is not surprising that Alexander Bürkle feels it is on the right track with the EPLAN Platform. Fabian Camek: "The decision was right. We have expanded our engineering portfolio and keep in contact more intensively with customers, who we save a lot of work".

Figure 6 Here we have the digital twin of the mounting panel

One of the goals for the near future is for customers to configure their projects on an EPLAN Platform provided by Alexander Bürkle, and then receive the (largely automated) planning with all parts lists, 3D views and circuit diagrams. The benefits of this new type of sharing tasks are enormous. Alexander Bürkle expects a 75% reduction in the time required for electrical planning. At the same time, this new approach to design will also change how customers work with mechanical engineers. Fabian Camek: "We are evolving from a control cabinet manufacturer and engineering service provider to a systems house". Alexander Bürkle's customers are following this development with great interest.

EPLAN Software & Service

EPLAN provides software and service solutions in the fields of electrical, automation and mechatronic engineering. The company develops one of the world’s leading design software solutions for machine and panel builders. EPLAN is also the ideal partner to streamline challenging engineering processes.

Both standardized as well as customized interfaces to ERP and PLM/PDM systems ensure data consistency along the whole value chain. Working with EPLAN means boundless communication across all engineering disciplines. No matter whether small or large enterprises: Customers can apply their expertise more efficiently. EPLAN wants to grow further with customers and partners and pushes integration and automation in engineering forward. Worldwide, EPLAN supports over 55,000 customers. Efficient engineering“ is the focus.

EPLAN was founded in 1984 and is part of the owner-operated Friedhelm Loh Group. The Friedhelm Loh Group operates worldwide with 18 production sites and 80 international subsidiaries. The entire group employs 12,000 people and generated revenues of around €2,6 billion in 2018. For the eleventh time in succession, the family business has won the accolade “Top German Employer” in 2019. In addition Friedhelm Loh Group was recognized as “Top vocational trainer” according to a study of Deutschland Test and Focus Money.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product