PRECISION MOLDING & THE INTERNET OF THINGS

There is no doubt that when manufacturing highly complex micro molded components, data can help to ensure a maximum level of repeatability in the micro injection molding process, create consistent quality, and mitigate defects. Data also provides the general benefits of reduced downtime through preventative maintenance and machine upkeep.

Terminology is quite interchangeable in this field. When discussing smart manufacturing many refer to the IoT, Industrial IoT (IIoT), or Industry 4.0. The actual term IoT was first used by Peter T. Lewis in 1985 to describe as he stated it “the integration of people, processes, and technology with connectable devices and sensors to enable remote monitoring, status, manipulation, and evaluation of trends of such devices.”

So while the term has been around for a few decades, the concept continues to develop and evolve as technology continues to advance through new hardware, and through the collection and analysis of data.

For precision micro molders in particular, the IoT allows for gains in production efficiencies, improved production quality, and reduced time to market. Machines can now communicate failure points and collect data that can be used to improve predictive and preventative maintenance, which in the long run improves uptime. Data analysis is used to predict and prevent failure; it indicates when intervention is required and recommends the necessary corrective actions. Troubleshooting is more efficient, which benefits both manufacturers and customers.

The drive to glean more – and better – data from industrial equipment and systems will continue to improve productivity in the micro molding sector as technology, sensors, and systems continue to evolve, to the benefit of the molders and their customers.

But there is something else that micro molders understand when looking at the IoT.

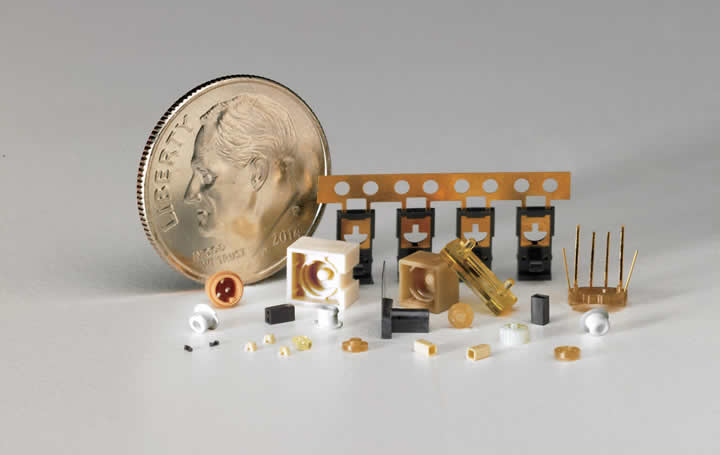

The very innovative hardware and components that enable smart devices or wearables represent a huge, dynamic, and growing market as very often these devices are small, intricate, and their manufacture is often driven by weight, cost, and time-to-market considerations. OEMs making components that drive IoT devices must engage with highly qualified and experiences micro molders in order to ensure the efficient and cost-effective manufacture of safety critical precision and micro components. Engaging with a qualified micro manufacturing partner early in the design cycle for new product development is vital to avoid multiple (and costly as well as time-consuming) design and tooling iterations.

Devices that Drive the IoT

To see whether something fits under the IoT umbrella, you really need to look at interconnectivity. Does one product work with another product? If you lock a window, does a door lock automatically as well? Are your light controls connected with your thermostat? As you walk up your garden path, do your lights turn on and your curtains close as you hit the remote control to unlock the front door?

These examples probably get us closest to a workable definition of the IoT. An IoT is a coordination between multiple devices, and it involves fitting devices with an on/off switch that is connected to the internet. We have seen over the last few years that the number of connected devices has ballooned into the billions, and this exponential growth in the IoT will be driven by the software and hardware that make it all possible.

Governments are deploying IoT applications to alert them to failed street lights, leaks in water systems, and full trash cans etc…. The IoT will also very likely have a major role in traffic control, and forest fire and landslide detection and the like. Remote sensing is already mainstream in many industries, office buildings, and in the energy supply.

However, it's the consumer applications that get the most attention, because they involve almost every industry and platform: health systems, home energy use, hardware, home building, electronics, and the entire category of wearables, including clothing.

Software-wise, interconnectivity is driven by the use of Bluetooth, devices wirelessly communicating with each other and thus making them intrinsically linkable. Hardware-wise, the key is sensors, or to be accurate “micro-sensors” without which there would be no IoT.

Micro sensors detect and measure temperature, vibration, and the effectively “see and hear” for devices. As we analyze the sensors used on many devices that make the IoT, we are looking into the area of MEMS (micro electro-mechanical systems), tiny components — sometime less than a thousandth of an inch in size — which are critical for IoT functionality.

Very often, MEMS are manufactured in much the same way microprocessors are manufactured, through a lithography process. These sensors can be paired with an application-specific integrated circuit or “ASIC”. This is a circuit with a limited degree of programming capability that is hardwired to do something specific. It can also be paired with a microprocessor and will likely be attached to a wireless radio for communications.

The application of MEMS sensors to the IoT-enabled markets will require sensors to shrink further and to work in an even more power-efficient way moving forward.

Today, MEMS are intelligent technical systems or subsystems with advanced functionality, which bring together sensing, actuation and data processing, and informatics/

communications. Therefore these systems are not only able to sense but also to diagnose, describe, and even manage any given situation. They are highly reliable and their operation is further enhanced by their ability to mutually address, identify, and work in consort with each other. Such smart systems are the hardware basis for the IoT

From a technology point of view, these smart systems are not limited to silicon–based technologies but integrate polymer-based technologies, printing technologies (for printed antennas, printed sensors, displays or batteries), different nanotechnologies (spintronic devices, CNT-based devices or devices based on embedded nanoparticles), and even embroidering technologies for sensors.

Engagement with a Micro Molder

Accumold is a micro molding and miniaturization expert that specializes in the manufacture of very small micro-sized parts and MEMS devices. With over thirty-five years experience working in an array of industries that demand fast turnaround and small complex parts, Accumold has been at the forefront of development in micro sensors and MEMS devices, and as such sees enormous opportunities to partner with companies developing IoT devices.

As with many projects that require specialist attention and expertise, MEMS and miniaturization projects connected with IoT applications benefit from OEM developers engaging with selected sub-contract manufacturers such as Accumold early in the design cycle. As a company, Accumold prefers to work as a product development partner with its clients ensuring that designs are right first time, and eliminating the need for costly and time-consuming reiterations and reworking later in the manufacturing cycle.

So, just one more thing remains. A call to action maybe. If you are an OEM looking to exploit the potential of the IoT, and you require a dedicated and experienced technology and applications expert to navigate the issues involved from move from concept to marketable product, engage with a qualified and experienced micro molder today, and make your ideas a reality as you exploit this exciting niche. The opportunities exist now, so why not begin to assess the credentials of your micro molding partner today!

About Accumold

Aaron Johnson is the VP of Marketing and Customer Strategy at Accumold. The company has grown to a 130,000 square foot fortified facility designed for assurance of supply, employs over 350 staff, and is a net exporter shipping all over the world every day from its Ankeny, IA, USA facility which runs 24 hours a day, 7 days a week.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product