Why Laser Technology Is a Good Automation Tool for Traceability

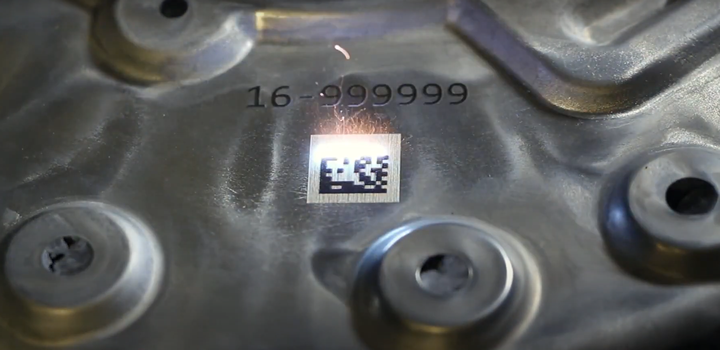

Traceability is an important part of the manufacturing process. Manufacturing items for mission-critical parts in industries such as aerospace, automotive, or medical, demand complete traceability from supply chains to finished products.

However, any time you add an extra step in your production process, you run the risk of additional maintenance or slowdowns.

Automating the traceability process is essential for manufacturers who want to avoid production bottlenecks, reduce production costs, and improve the marking quality to meet OEM traceability requirements. Automation reduces the amount of work that needs to be performed manually by humans and speeds up repetitive tasks. It also eliminates errors and inconsistencies.

One of the best ways to accomplish these goals is by automating your traceability process using laser marking.

Laser marking has many benefits, including:

- Keeping up with huge production runs

- Requiring minimal maintenance and downtime

- Easy changeover for batch production

- Marking parts in movement

- Rapid integration

The Benefits of Laser Marking for Traceability

Let’s examine these capabilities and benefits of laser marking in more detail.

Benefit #1: Laser Marking Is Capable of Keeping up With Huge Production Capacities

When it comes to production capacity, laser marking has no problem keeping up with huge volumes.

Power can be scaled to individual manufacturers’ needs, as a 100W laser works nearly twice as fast as a 50W laser. For most applications, a 100W pulsed fiber laser is enough. In the stamping industry, for example, a 100W laser can mark a part every second.

Multiple lasers can also be installed on a line to process more parts at the same time. In most cases, however, you are better off using a more powerful laser to minimize the footprint, complexity, and costs.

Benefit #2: Minimal Maintenance Means Minimal Downtime

Keeping up with the production speed is not the only way to pretevent bottlenecks. You must also keep downtimes to a minimum to hit your production goals.

When it comes to low maintenance levels, laser marking technology requires less maintenance than any other marking solution. Other types of marking systems require regular maintenance, primarily due to mechanical wear, such as dot preening and inkjet printing.

With dot preening, a lot of mechanical tuning is required. In inkjet printing, the nozzle must be cleaned regularly to avoid clogging.

Laser technology is different. Because there are no moving parts, there’s no mechanical wear to worry about. There are no consumables either that require replacement or maintenance concerns.

Wear from repeated contact with a part’s surface is eliminated with laser marking, which employs a non-contact technology. If the laser operates at a safe distance from the part surface, the dust generated by the laser process does not cause problems. A dust extraction nozzle installed near the marking area can also minimize maintenance concerns even more.

Benefit #3: Easy Changeovers for Batch Production

Not all automated environments need to keep up with high volumes. Sometimes, parts are produced in batches. So, manufacturers need to be able to adjust the marking process for different types of parts. To minimize downtime, changeovers must be quick and simple.

Laser markings systems can be automatically adjusted for different part models, so there is no manual changeover required. Once the laser is preconfigured, operators only need to push a button to launch a software change that automatically adjusts the laser for different parts. Instead of having to tune parts or swap out components, changeovers occur instantly with a button push and do not require any mechanical adjustments.

For example, if the distance between the laser and the part being marked changes, autofocus features will detect and adjust the laser process automatically. If the location of the marking changes, but it is still within the typical 300 x 300 mm window, the marking location can be moved without any adjustment to the laser.

Benefit #4: Marking Parts in Movement

Ingots, aluminum extrusions, brake discs, and many other manufactured parts use conveyors to move parts through the production line. If you have to stop the conveyor for even a short time for marking operations, your entire process slows down.

Laser marking can be done on the fly to mark these parts while they are moving on the conveyor. Because laser marking is a non-contact technology, marking can occur while parts continue in motion.

Making this possible is relatively simple. When supplied with an encoder signal, laser marking technology can actively compensate for the part’s linear speed and eliminate the need for the conveyor to stop. Unless the conveyor already stops for other operations, marking on the fly is one of the best ways to prevent bottlenecks in your production pathway.

Benefit #5: Can Be Integrated Quickly

Production lines are typically stopped during most integrations. Since that equates to expensive downtime, you want to minimize it as much as possible.

Some other marking technologies require extensive adjustments. They can be full of surprises during the installation process that take time to work through. Laser systems, however, can be fully configured in advance. When they arrive on-site, lasers have already been pre-calibrated and pretested in a lab based on the marking requirements. The laser marking recipe will be the same during tests in the lab and on the shop floor, so it’s ready to go right away.

Many turnkey laser solutions already exist, so laser markers can be delivered ready to be used without the need for on-site mechanical adjustments.

Traceability Is About More Than Just Compliance

Many manufacturers still view traceability as something they are required to because of compliance needs — either because of OEM requirements or as required by law. However, traceability data should be viewed as more than just meeting compliance.

The data produced — and the traceability it creates — can be a goldmine.

In case of a product anomaly, traceability helps pinpoint root causes more quickly as part of your quality assurance and quality control programs. Manufacturers can more readily take corrective and preventive actions (CAPAs).

If a product fails in the field or there is a product recall, traceability can save significant time and money by reducing the recall size. You can pinpoint where the failure occurred in the manufacturing process and only recall the parts that went through that path.

Traceability also helps fight product counterfeiting. By creating unique identifying codes, every part can be tracked from the supply chain to the end-user.

Creating a robust and efficient traceability process does not have to be difficult. Laser marking systems are the future. They provide high-quality and reliable data that is unmatched by other technologies. Lasers can be optimized for each application to meet specific requirements and changeovers happen instantly.

With laser marking technology, there is almost no maintenance required, no mechanical adjustments needed, and no need to stop production lines for the marking process.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product