How Product Catalog Management Supports Circular Supply Chains in Manufacturing

Most ERP and PLM systems track products only through production and sale, not reuse, refurbishment, or recycling. This fragmentation causes material loss, inefficient remanufacturing, slow reverse logistics, and compliance failures.

The Evolution of Mass Custom Manufacturing: Why the Industry Needs a High-Velocity Shift

HVMC is not just faster production but a fundamental reimagining of how custom manufacturing operates. By standardizing and automating processes without sacrificing the ability to tailor products to specific needs, HVMC has the potential to transform the landscape.

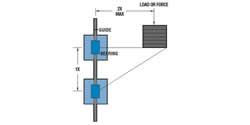

What is the 2:1 Ratio For Linear Plain Bearings?

The 2:1 Ratio represents the maximum allowable moment arm distance relative to bearing length without causing binding or motion restriction, ensuring optimal performance in plain linear bearings.

Unleashing the power of gen AI in manufacturing

While Gen AI is taking off across numerous organizations and industries, some sectors have been slower to get on board. Traditional manufacturing is behind the Gen AI curve as disparate data and lack of digitization are creating obstacles on this transformation journey.

Optimizing Your IT Ecosystem: Is It Time for a Tech Stack Audit?

A tech audit can serve as a diagnostic tool, flagging vulnerabilities within your packaging company's IT infrastructure before they impact the health of your business.

The Hidden Cost of Convenience - Why 3D Printing Shouldn't be Left only to an Algorithm

At first glance, the idea of an entirely self-service 3D printing experience is appealing. Who wouldn't want an instant quote? Who wouldn't prefer the simplicity of a few clicks over a back-and-forth exchange with a human?

Dealing with the Aftermath of M&A via Configuration Management

Manufacturers can use deals to leverage new technology capabilities and diversify their supply chains. However, as businesses grow and merge, the need to manage complexity becomes greater.

These Innovations in Telecommunications Are Elevating Manufacturing in 2025

From 5G to edge computing, innovations are reshaping how factories operate and redefining smart manufacturing's potential.

Bridging the Gap: Overcoming the Barriers to Manufacturing Digitization

Despite decades of technological advancements, a staggering 70% of manufacturers still rely on manual data collection in 2024.

How MRP Software Transforms Manufacturing Efficiency and Reduces Waste

This article investigates the role MRP software plays in manufacturing process optimization as well as its capability to decrease waste volumes which drives business competitiveness during fast-paced industrial markets.

Manufacturing's 2025 Rollercoaster: How to Keep Calm and Carry On

Beneath signs of growth, very real challenges like labor shortages and supply chain vulnerabilities continue to test our sector's resilience. These problems are further exacerbated when government policies are shifting - and decisions are changing - nearly every day.

What Steel and Aluminum Tariffs Could Mean to Steel King and How Those Tariffs Could Impact Everyday Business

A number of people have been reaching out looking for comments on President Trump's recently announced 25% tariffs on all steel and aluminum imports into the United States and what that means to Steel King as well as how those tariffs could impact everyday business.

Leveraging the Virtual Twin Experience for Decarbonization in the Metals Industry

In this article, Prashanth Mysore, Senior Director for Strategic Business Development at DELMIA, explores how Virtual Twin technology can transform your business operations, whilst also addressing decarbonization.

Automation and advanced technologies boost efficiency

While automated systems remain popular tools for optimization, CPG companies also are adopting advanced technologies such as digital connectivity, data collection functionality, AI, augmented reality, virtual reality, and advanced human/machine interfaces.

How ERP streamlines lean manufacturing

With the increasing adoption of lean manufacturing, which focuses on minimizing production inefficiencies and waste, manufacturing ERP software has become critical.

Records 1 to 15 of 1201

Featured Product

Parvalux by maxon - AC or DC electric motors for conveyor systems?

The material handling industry uses conveyors to ensure that products are distributed effectively, AC or DC motors are chosen depending on the weight it needs to carry and the speed at which it needs to work. Learn which type of conveyor motor might be best for your application and how Parvalux can help you select a geared motor from stock or create a fully custom design.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)