Optimizing Your IT Ecosystem: Is It Time for a Tech Stack Audit?

A tech audit can serve as a diagnostic tool, flagging vulnerabilities within your packaging company's IT infrastructure before they impact the health of your business.

Tariffs Unwrapped: How New Trade Policies Could Reshape the Packaging Industry in 2025

The impending reinstatement of tariffs under the Trump administration has the packaging industry bracing for significant changes in 2025. With proposed tariffs the packaging sector is set to face complex challenges that could reshape operations, costs, and competitiveness.

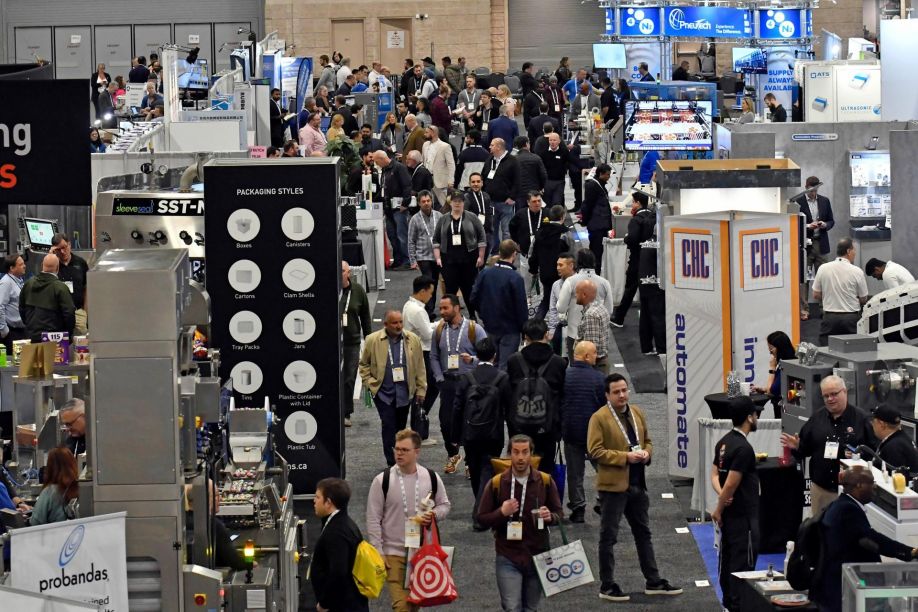

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

This brand-new regional show promises to connect industry leaders, innovators and decision-makers while showcasing cutting-edge technologies that will shape the future of manufacturing across more than 40 vertical markets.

PACK EXPO 2024 Product Preview

PACK EXPO International 2024 takes place November 3rd - 6th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

A Packaging Look-Ahead for 2024 and Beyond

As packaging converters and their brand/retailer clients look to the future, there are four key areas of focus that are getting a lot of attention: Artificial Intelligence, Sustainability, Automation, and Hiring and Retaining talent.

PACK EXPO 2023 Product Preview

PACK EXPO 2023 takes place September 11th - 13th in Las Vegas, Nevada. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

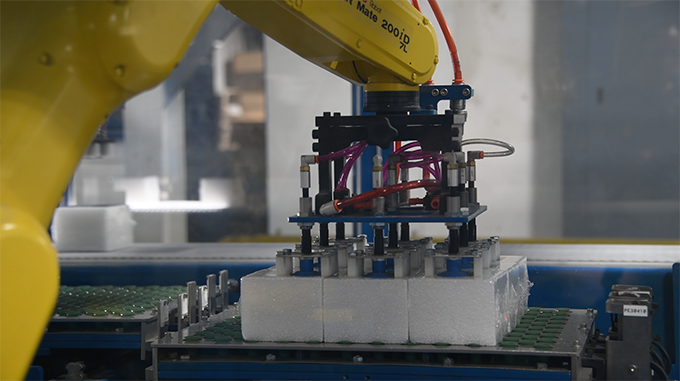

Tompkins Industries Reaches New Heights with its Vertical Lift Automation System

The automated vertical lift project kicked off in January 2022 and relied heavily on technical assistance from the team at PathGuide to incorporate the automated vertical lift into Latitude.

Insights from Brenton Engineering Company

Equipment Flexibility Key to Accommodating Changing Applications , The Upside of Automation on Your End-of-Line Operation, The Value of Project Management

Using Infrared to Ensure Package Seal Integrity

Using infrared inspection as part of a quality control program allows for inspecting all package seals in the production line. Companies can ensure package seal integrity, promote product quality, and elevate customer satisfaction by implementing package line inspection.

How to Mitigate Supply Chain Risk in the Food & Beverage Industry

Transparency, sustainability, waste reduction and food safety are all significant concerns in need of addressing if food manufacturers want to stay relevant, competitive and optimally profitable, and relying on old strategies is no longer a viable option.

Why food packagers need to trust AI - It is time for food packagers to embrace smart technologies

A survey by McKinsey states that the adoption of automated technologies in the food and beverage industry is relatively slow compared to other sectors, with only 48 per cent of manufacturers considering themselves ready for Industry 4.0.

IDS focuses on sustainability in shipping

IDS is convinced that the changeover to sustainable action is the only right way forward and tries to develop resource-saving solutions together with business partners. After all, relatively "small" changes can make a big difference - for the environment and for the company.

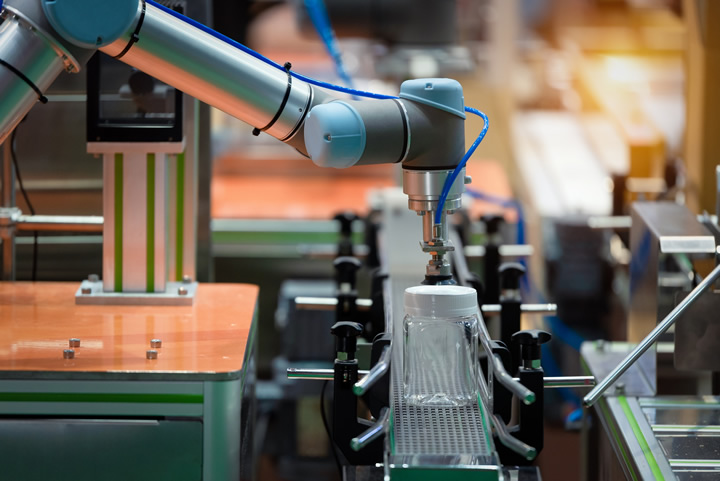

Time for manufacturers to make their packaging lines smarter

According to the latest report by PMMI Business Intelligence, there is a growing need for manufacturers to roll-out the Industrial Internet of Things (IIoT) across their enterprise. However, these companies should identify their existing "IIoT blind spots" before they do so.

How-To Guide on Mastering PACK EXPO Connects

With so many activities and over 2,600 scheduled demos taking place at PACK EXPO Connects, here is every preparation tool attendees need to ensure a successful event.

Packaging is Essential in Time of Need

During these unprecedented times, it is of utmost importance to keep packaging lines moving, especially for manufacturers of essential consumer packaged goods (CPGs). There's no way around it.

Records 1 to 15 of 32

Featured Product

KEB VFDs for High Speed Motor Control

KEB's VFDs are the key to unlocking peak performance in your high-speed machinery. Engineered for precision control, even without feedback sensors, our F6 and S6 drives utilize advanced software and high-frequency output. This ensures smooth operation, reduced vibration, and optimal efficiency. Whether you're building turbo blowers, power generation systems, or other high-speed applications, KEB VFDs deliver the reliability and performance you need.

.jpg)

.jpg)