Creating the Perfect Thanksgiving Meal: Lessons in Production Planning, Scheduling, and the Connected Worker

Imagine preparing a Thanksgiving meal for a large family. Production planning is like deciding on the recipes, sourcing ingredients, and planning each step so everything aligns smoothly.

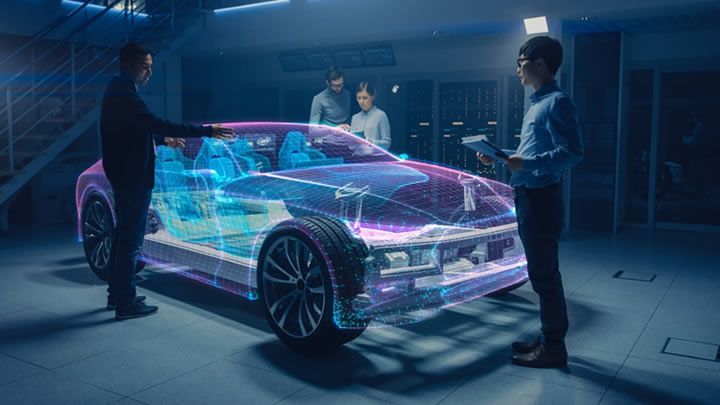

Industrial Metaverse: Pioneering Remote Maintenance Solutions

The Industrial Metaverse is emerging as a transformative technology in manufacturing and maintenance, blending advanced technologies to create a more efficient and responsive operational landscape.

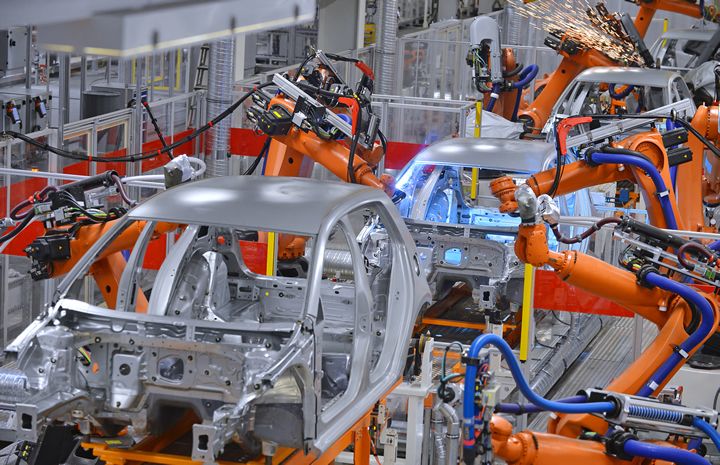

UK's Auto Factories Embrace the Advanced Robotics Revolution

The United Kingdom's automotive production sector is experiencing a fifth industrial revolution (5IR). Although the fourth industrial revolution (4IR) started just over one decade ago, the next generation of advanced robotics in manufacturing has already arrived.

Investing in the UK's injection moulding sector - The case for all-electric machines and robotic integration

Traditionally, our manufacturers have relied on hydraulic-powered injection moulding machines in their operations. However, the industry is now at a crossroads, faced with the imperative to embrace technological advancements for sustainability and cost-effectiveness.

The importance of strong supply chains - Fast delivery drives efficiency in CNC manufacturing

One of the foremost ongoing obstacles is demand forecasting, where inaccuracies can lead to either stock shortages or excess inventory, both of which can have significant financial implications

Choosing Zero Trust Network Access Over Virtual Private Networks is a C-Suite Decision

PwC describes today as the "age of continuous reinvention" in its 27th Annual Global CEO Survey report. One of the most startling findings is that 45% of CEOs do not believe their company will be viable in 10 years if it stays on the current path.

The Future of Automotive Supply Chains: Integrating Sustainability with Operational Efficiency

The automotive industry is at a pivotal crossroads, driven by rapid advancements in vehicle technology and increasing regulatory pressure. As the landscape evolves, automotive manufacturers must adapt their business models and supply chains to remain competitive.

Developing the Talent to Lead US Manufacturing Tomorrow Starts Today

Reshoring efforts, a wave of retirements, and advancements requiring new skill sets have coalesced to create labor shortages throughout the sector, prompting 65 percent of manufactuers to say that attracting and retaining talent is their primary business challenge.

Leveraging Voice-Directed Picking to Boost Warehouse Productivity

This innovative solution allows workers to receive audio instructions via headsets, keeping their hands and eyes free for picking tasks. Here is how you can use voice-directed picking to boost your warehouse's productivity.

How the US Election Could Shape Global Trade and M&A

With potential changes to trade policies and international partnerships, the global supply chain landscape could be redefined. For example, a Trump administration may lean into protectionist trade measures, aiming to reduce reliance on China.

Equal Parts: Assessing the Viability of Large Format Additive Manufacturing

Whether you're a manufacturer already embracing the technology or still assessing what it could do, there a few things to consider when it comes to evaluating the suitability of the technology for specific parts production and which parts could be optimized with LFAM.

Conquer Quartz Limitations with MEMS Precision Timing for Industrial Automation

Today there is a better alternative for industrial automation with silicon Micro-Electro-Mechanical Systems (MEMS) timing solutions that overcome limitations of legacy quartz devices. Read on to explore why successful industrial automation is a matter of timing.

Future-Proofing the Warehouses of Tomorrow

Network infrastructures must meet the demands of dynamic, 24/7 operations, enabling warehouses to run seamlessly without downtime, and wireless mesh networks offer a revolutionary approach to achieving full connectivity and supporting sophisticated warehouse robotics.

Custom Corrugated Box Manufacturer Grows by 40% in 10 Months

Custom corrugated packaging manufacturer Value Added Packaging from Ohio moved from a legacy ERP system to a modern cloud-based software and grew 40% in 10 months.

Focus on Revitalizing American Manufacturing

The transition to a service economy has been rough, and many Americans feel they have fallen through a gap between insufficiently low-paying work and professional careers they can't access.

Records 1 to 15 of 2808

Featured Product

T.J. Davies' Retention Knobs

Our retention knobs are manufactured above international standards or to machine builder specifications. Retention knobs are manufactured utilizing AMS-6274/AISI-8620 alloy steel drawn in the United States. Threads are single-pointed on our lathes while manufacturing all other retention knob features to ensure high concentricity. Our process ensures that our threads are balanced (lead in/lead out at 180 degrees.) Each retention knob is carburized (hardened) to 58-62HRC, and case depth is .020-.030. Core hardness 40HRC. Each retention knob is coated utilizing a hot black oxide coating to military specifications. Our retention knobs are 100% covered in black oxide to prevent rust. All retention knob surfaces (not just mating surfaces) have a precision finish of 32 RMA micro or better: ISO grade 6N. Each retention knob is magnetic particle tested and tested at 2.5 times the pulling force of the drawbar. Certifications are maintained for each step in the manufacturing process for traceability.

.jpg)

.jpg)

.jpg)

.jpg)