In absence of Manufacturing Execution Systems (MES), reporting is purely historical and is often available too late to take action on its findings. MES enables non-conformances to be addressed in the present and minimize their potential impact.

Bob Miklosey | Aegis Software

Every aerospace manufacturing organization needs a quality system. The differentiator is how readily one can react to a non-conformance and how frequently report their quality metrics. In absence of Manufacturing Execution Systems (MES), reporting is purely historical and is often available too late to take action on its findings. MES enables non-conformances to be addressed in the present and minimize their potential impact.

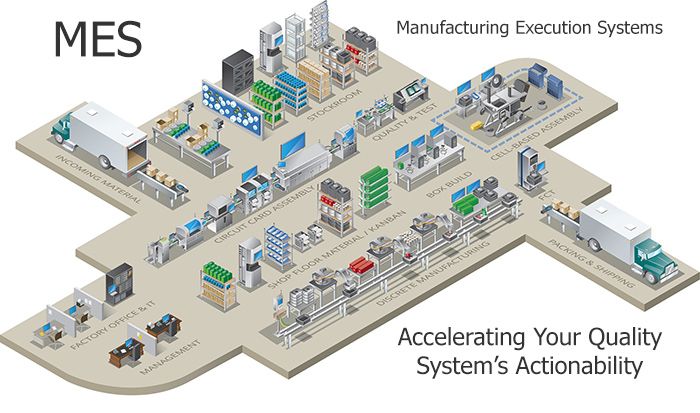

Irrespective of company size and scale, quality systems play an essential role for aerospace and defense manufacturers for mitigating risk and meeting compliance with industry standards like AS9100. What can differentiate one manufacturer’s quality system from another? How readily they take action against a non-conformance and how frequently they report key quality metrics, which is enabled through a modern manufacturing execution system (MES). In absence of MES and having production information exist in digital form, a critical event may find itself reported in a historical context and often too late to properly react to its findings. MES is the essential complement to the organization’s quality management system (QMS), where together they can accelerate process development, improve production control, deliver regulatory compliance, and provide real time visibility to management.

In many manufacturing landscapes, a formal MES system still is not present. Instead, the ‘system’ in place is often a combination of point solutions and paper processes. This archipelago of components accidentally evolved through solving a given challenge critical at a given moment. Consider the situation within a particular factory; test results needed to be reported to an end customer and a database was created to store its collected data. Material counterfeiting emerged as a concern where traceability became mandatory and this challenge was addressed by stockroom personnel writing each lot number on a picking list. A customer required all torque and other measurements to be recorded as part of their unit build history so in response, operators record parametric data in a web form. However, most production areas still follow work instructions developed in an office application. The quality policy requires inspectors to record defects found on the product onto a tick sheet and then add details to a ‘toe tag’ traveling with the product for the benefit of a technician to perform a repair, and if severe, they then duplicate the effort to initiate a non-conformance event in another system. These actions are then individually printed and assembled into a packet, and physically accompany the related production units in process as part of its traveler. Throughout the entire case example above, the manufacturer has actually met the explicit requirements for data management in aerospace manufacturing, but the manner in which it has been achieved is not in any way efficient, cost effective, simple, or expedient.

Beyond the hidden costs of managing a spectrum of isolated tools varying in age and condition as depicted above, a key quality challenge is the ability to agilely react and report when a non-conformance occurs within this environment. Factory floor personnel are in effect conditioned to limit their defect collection as it becomes more of an event and less of a natural activity while performing their operations. Because these occurrences may require entry found in multiple systems or paper forms and can consume a significant amount of time to report, there may even be rules imposed upon the inspector to only submit issues requiring more than ‘n’ minutes to correct, leaving a majority of in-process quality issues unreported. The result is an inaccurate reflection of quality metrics and an inability to report them in an effective timeframe for broader correction, prevention, and improvement to occur.

The experience radically changes when MES is implemented in a holistic approach and one that is more natural for factory floor personnel, engineers, and management. Quality functions, while essential, are only one aspect to the overall operational coverage of MES. When properly designed, MES seamlessly considers all activities conducted at an operation, from setup to execution, whether performed by a person or a machine. At a manual process for instance, the first quality control occurs when the operator’s certification is validated to ensure they possess the appropriate skills to perform the required tasks. The operators are then instructed to prepare their workstations and have the required material and tooling validated for use. Their work begins by either entering a build quantity or inputting a barcode for serialized unit tracking, where the workpiece itself is then validated to ensure it is properly traveling along its route sequence and possesses a valid status to proceed. They then dynamically interact with paperless instructions, engaging with them at a granular level through each activity they perform while being presented with related detail found in documents, videos, and drawings, and prompting them to capture measurements, serialized subassemblies, and other attributes that are also validated. A supervisor or peer may then be prompted to review and approve any or all of these activities. The totality of this experience instills quality through successful closed-loop checks and preventive measures without degrading production line performance or ergonomics.

Whether a given operation is primarily intended for assembly, processing, inspection, or test, it must be thought of as an opportunity for quality. While an operator may be performing a pure assembly task, they may uncover an abnormality needing to be reported. MES enables all personnel to serve in a quality role and capture all in process defects in the same manner as an inspector dedicated to a QC step. Advanced MES systems further enhance the defect collection experience through graphical onscreen input referencing the product design CAD and imagery. Technicians diagnosing test failures on a top-level assembly may identify the root cause by relating it to one or multiple defects found within a child assembly. It is in the hands of the system’s quality administrators and the quality policy they define to identify which events automatically trigger a nonconformance for further review and disposition as part of their corrective and preventive action (CAPA) process, relieving the need for redundant data entry in a secondary system and all of which are naturally occurring through the operator’s actions.

The byproduct of all these actions is the rich analytical data living within a centralized MES database, immediately available for reporting and action, and bringing KPIs and quality metrics to life in real time. Staff outside the office view current production activity on their mobile devices. Managers receive daily quality reports directly sent to their inbox. Engineers conduct ad hoc data analyses on drill down charts and pivot tables at weekly action meetings. Shop floor personnel and visiting guests view dashboards running overhead displaying real-time metrics from areas, lines, and equipment. MES not only changes how data is collected, it engages all organization levels to take an active role in quality.

A properly designed MES system readily adjusts to the unique quality challenges found in aerospace and defense manufacturing. It adapts to the manufacturing process breadth found inside an enterprise’s manufacturing operations, which can include machining, forming, electronics, cable/harness, module, and large-scale assembly dwelling over extended periods. It eliminates the risk of an operator referencing the wrong BOM or work instruction revision and actively informs them of change notices (ECNs) targeted for the product and the process they are performing. It follows the product’s complete lifecycle and maintains its unified history through its initial production, ad hoc re-routes for repair, refurbishment, field return, MRO, and any other process it undergoes.

When MES is holistic in its adoption and implementation it drives a manufacturing culture of in-process quality from beginning to end in the enterprise. Both personnel and end customers benefit from the immediacy of its information and reaction, where reliance upon its preceding fragmented methods are unthinkable. Its impact on the overall quality system is unmistakable, serving in an indispensable capacity as the in-process contributor to a quality system for true actionability. MES is thereby treated as essential of a pillar to the organization’s systems as ERP, completing the manufacturers digital footprint for attaining the highest quality output and achieving operational excellence.

Bob Miklosey is the Vice President of Product Management at Aegis Software, a leading provider of Manufacturing Execution Software (MES) that gives manufacturers worldwide the speed, control, and visibility they require. He is responsible for driving product innovation and strategy, directing the company toward its goal of empowering today’s digital manufacturer. Prior to joining Aegis, Bob held leadership positions at Quad Systems Corporation and Tanon Manufacturing EAI, where his passion for instilling digitization into factory processes began.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product