Unleashing the potential of smart factories: The critical role of IoT and software engineering

As businesses strive to stay ahead in this era of smart factories, the convergence of IoT, AI, digital twin, advanced HMI, and robust cybersecurity measures has become indispensable. At the heart of all of this is the seamless interplay between IoT and software engineering.

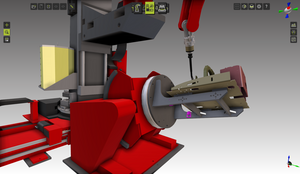

How Simulation Can Secure Your Robotics Investment

Robotics simulation can be defined as a digital tool used to engineer robotics-based automated production systems. Essentially, robot simulation employs a digital representation to enable dynamic interaction with robot models and machines in a virtual environment.

Securing the OT edge with SASE

Manufacturers have become increasingly reliant on cloud-based resources, such as Software-as-a-Service (SaaS) applications and data migrating from the data center to multi-cloud environments. This requires a new model for secure network access.

Using 3D PDF to Easily Share Your 3D CAD Data

Organisations are having to find new mechanisms that enable their teams to quickly create interactive documentation containing representations of their native 3D CAD data, that can easily be shared with non-CAD users, their customers and wider supply chains.

Case Study - Reducing Automation System Risk with Simulation and Emulation

Increasing global competition and an awareness of the need to pivot away from on-site commissioning to safer and more cost-effective virtual methods are the main drivers behind a growing interest in industrial analytical simulation.

Inventory Management Software with Capabilities of Bill of Materials BOM

A Bill of Materials (BoM) is an extensive list of raw materials, by-products, components, assemblies, and packaging material needed to make a finished product.

Virtual Reality: Turning Short-Term Wins Into Long-Term Success

Despite the fact that many commercial enterprises are already leveraging new technologies like virtual-and augmented reality (AR)-to unlock productivity and growth, this technology has yet to reach widespread adoption across the manufacturing sector.

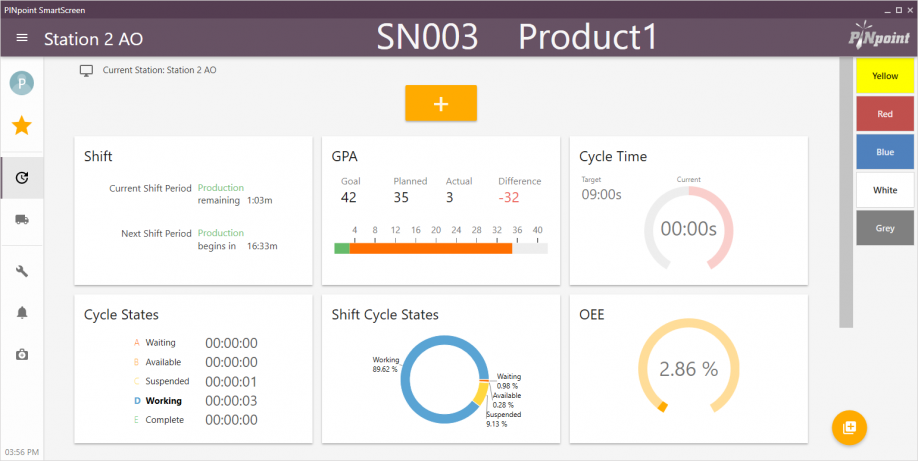

Revolutionary Technology Addresses Industrial Downtime

New technology is poised to transform the way machines operate in the industrial environment. Costly consultants and confusing spreadsheets are out, and easy to understand dashboards are in.

Embedded Software Market to cross USD 20 billion by 2025

The increase in the demand for open source Linux software & RTOS software is expected to offer a lucrative growth to the embedded software market.

The Applicability of Mobile Software Solutions in Manufacturing Facilities

There are many innovative use-cases in manufacturing for mobile software. Some of the more prevalent examples will be discussed below.

Partnership for China 2025: RISONG and CENIT

China has long since ceased to be the "workbench of the world". In the manufacturing industry, rising wages and the "China 2025" development program are constantly accelerating the demand for automation solutions.

How to Optimize the Scalability & Performance of a Multi-Core Operating System

White Paper - Architecting a Scalable Real-Time Application on an SMP Platform

How Do Touchscreens Motivate Assembly Line Workers to Do Quality Work on Time?

The touchscreen user interfaces and software not only motivate line workers, they create a more team based approach to manufacturing execution that instills a new culture, and closed-loop of accountability in the factory

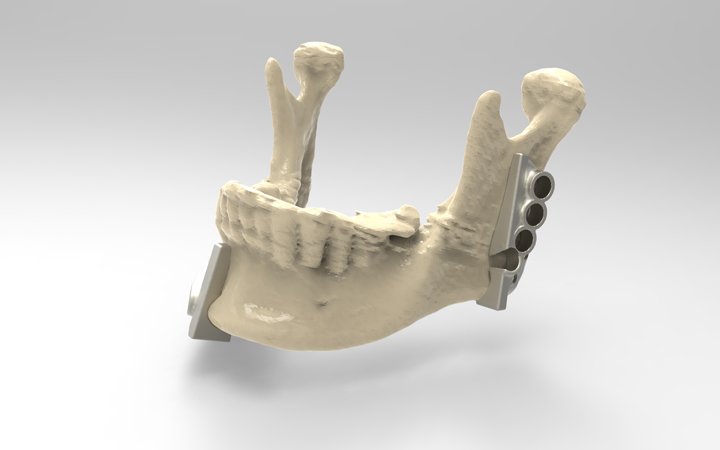

3d Modelling and Printing - Saving Theatre Time and Providing Excellent Patient Outcomes

In a recent project, Renishaw used its additive manufacturing (metal 3D printing) expertise to help the University Hospital of Wales (UHW) treat a patient who suffered cancer of the lower jaw and required removal of the affected region coupled with reconstructive work.

Robot welding: More efficiency for programming and equipment fabrication

Crown relies on FASTSUITE Edition 2 for offline programming of robotic welding cells.

Records 1 to 15 of 35

Featured Product

Quality assurance in the manufacturing industry

Efficiency and precision with CSP software. In the highly competitive world of manufacturing, quality assurance is a critical factor for success. CSP offers you state-of-the-art software solutions specifically designed to ensure the highest standards of quality assurance in the manufacturing industry.