Increasing global competition and an awareness of the need to pivot away from on-site commissioning to safer and more cost-effective virtual methods are the main drivers behind a growing interest in industrial analytical simulation.

Case Study - Reducing Automation System Risk with Simulation and Emulation

Case Study - Reducing Automation System Risk with Simulation and Emulation

Case Study from | Emulate3D

Increasing global competition and an awareness of the need to pivot away from on-site commissioning to safer and more cost-effective virtual methods are the main drivers behind a growing interest in industrial analytical simulation. Once the virtual product flows and operation sequences have been understood and developed, the next step is the virtual commissioning of the control systems before installation and ramp. These virtual methods serve to reduce the risk associated with automation systems, shortening development and commissioning times, and are an essential part of the new normal.

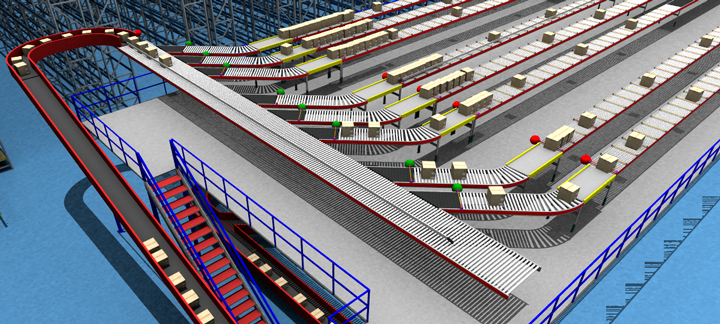

High speed merges frequently form the bottleneck and understanding their behavior is essential to the system success

A leading big box retailer required the statistical verification of the design of a new flexible distribution center for both its retail outlets and e-commerce, and Emulate3D was brought in by the system integrator to support the simulation modeling and experimentation phase of the project. Although the large physical scale and number of mechanical parts comprising this type of project is often an initial challenge, it is frequently surpassed by the complexity of the order processing systems which need to be accurately replicated within the model in order for its performance and results to be representative of the real thing, and therefore useful. While it is possible in many cases to connect to the actual order control system (OCS), it is rarely appropriate to do this for several reasons. First, the amount of detail required by the OCS to create the subset of data necessary for the simulation makes the time and cost excessive. Second, simulation models need to run extremely fast in order to generate results in a shortened time frame so multiple experiments can be used to create results to help users take good decisions, and OCS are not designed to do this. Third, and most important, the model needs to be flexible and easily modified, so that many experiments with different operational parameter sets can be created and run quickly. Spreadsheets are ideal for this and form the basis of most data-driven industrial simulation models.

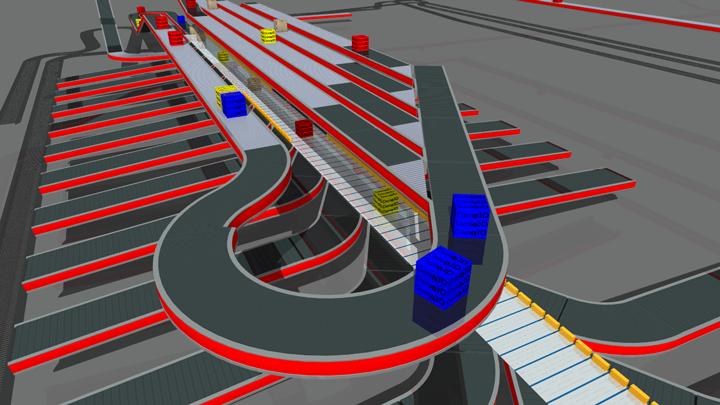

Simulation can help understand the most profitable way to run an automated system under any conditions

While the OCS inevitably forms a large part of any distribution system, a high speed sorter of some kind is often the central bottleneck which demands considerable attention. Not only are they logistically challenging, but the physicality of driving numerous combinations of various box sizes through them at high speed necessitates a high degree of confidence in the accuracy of the model and how closely it replicates the behavior of the real system. This project featured a multi-input sawtooth merge which became the focus of the experimentation phase.

Sim3D is the discrete event industrial simulation product used to model this system and to run the experiments necessary to evaluate the proposed system design. Simulation models come in all different sizes and with various requirements, so Sim3D users can choose from among several fundamental approaches to best suit their needs. A clear example of this is when a modelled system contains a returns process, where containerloads of boxes are introduced to a sorting system of some kind. These boxes will be various shapes and sizes and are often piled on top of each other. Only a fully volumetric physics approach will be adequate to model this with any degree of accuracy, if that is what is required. At the other end of the scale are high product flow models like this ecommerce project where the main imperative is execution speed. In this case, volumetric physics-based accuracy is unnecessary and linear mode is employed to direct the system to execute as fast as it can.

Data-driven simulation models are an exciting part of any automation project. The model brings together experience and ideas and it provides the first real insight into how the system will behave. Initially a development sandbox to fine tune the dimensions of buffers and to help with resource choice, allocation, and use, it quickly becomes the center of all discussions around throughput and operation. While this is to be welcomed as a part of the overall design verification, it needs to be efficiently managed in order to ensure that it doesn’t lead to scope creep and project delays.

Focus on the sawtooth merge as the bottleneck was appropriate, and much of the experimentation phase was spent ensuring that the control system propagating back from the merge was delivering product in a timely manner. While many end users have a tendency to insist on the importance of the peak throughput, it should be noted that the majority of the running time of any system will be somewhere below the peak, and it is therefore important to ensure this mode is as efficient and robust as possible. This project included the definition of several dozen sets of operational parameters, about half of which were below peak. While the bottleneck sawtooth merge was less used, there remained plenty of opportunity to run the rest of the system efficiently with planned redundancy enabling convenient maintenance and a very high degree of overall system availability.

Upon the successful completion of this simulation project, the client announced a further very similar project. While the data driving it will be all new, there may be virtual physical elements from this project which can be reused in the next. The OCS is likely to be very similar and therefore much time can be saved in reusing that core element.

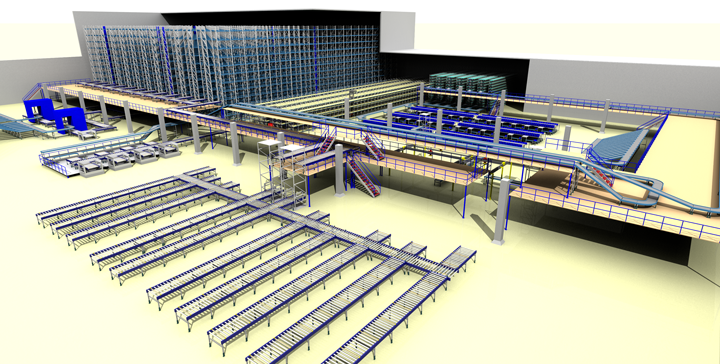

The simulation analysis of product flows and the virtual commissioning of controls help reduce time on site

While this simulation project and the operational understanding it brought were key parts of the signing off procedure to go forward with the system build, the model remains active as the project progresses beyond the design and development phase. There may be layout or performance modifications for any number of reasons, but more significant will be the impact of any implementation or product mix changes the system stakeholders may introduce in the time it takes to build and implement the real system.

There is a further allied phase of work which begins once the system design is signed off, and it is a further virtual approach to saving time and money later in the project, and that’s the virtual commissioning of the control system. At this point the model can usefully be broken down into smaller operational elements where one or more local or area controllers can be connected to the model in order to develop and test the real control system. The model detail matches the real world in a way that a simulation model doesn’t need to do in order to verify throughput, and doesn’t want to do in order to maintain high execution speed. Virtual commissioning, or emulation models run in real time as they are connected to actual controllers, and their aim is to take controls testing off the critical path by virtualising it. The equipment model and the virtual loads in it interact with the control system in the same way their real replacements do, providing an accurate and reliable way to ensure the correct operation of the control system and associated equipment before going on site. Time spent on site commissioning the system is significantly reduced, which decreases your risk, and costs are more closely controlled.

Emulate3D by Rockwell Automation develops a range of industrial design and development software focused on automation systems. Simulation helps users to communicate and develop their ideas cost-effectively and efficiently in order to reduce the risk associated with the automation investment. Emulation takes controls testing off the project’s critical path and enables users to reduce highly variable on-site debugging and commissioning time, making project timelines more predictable. Demo3D, Sim3D, and Emulate3D are used around the world by thousands of engineers to produce better designed and more reliable automation systems.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product