Energy Efficiency in Manufacturing and Data Management

Energy consumption is growing exponentially, while energy creation is increasing only incrementally. This imbalance requires innovative solutions. At Delta, we tackle this challenge from both sides-enhancing energy creation while optimizing energy consumption.

Edge Computing and AI in Manufacturing

With Tacton we wanted to give users the flexibility and configuration options they need to outfit their facility, while ensuring the system was reliable, secure, and easy to install.

How AI is reshaping the edge computing landscape

How much computing power is needed at the edge? How much memory and storage are enough for AI at the edge? Minimum requirements are growing as AI opens the door to innovative applications that need more and faster processing, storage, and memory.

Embrace the edge to avoid unscheduled downtime

One of the key metrics for process efficiency is overall equipment efficiency (OEE). This KPI is related to the availability, performance and quality of the production process. High OEE often means good revenue.

Sustainable manufacturing at the edge

In the wake of landmark climate event, COP26, manufacturers are striving to align their activities with the global net zero targets. But the sector has a long way to go. It currently produces more than 16 gigatons of carbon dioxide (CO2) each year.

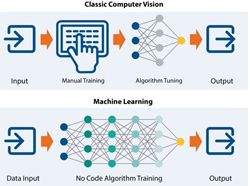

AI for End-to-End Quality

Artificial intelligence (AI) is gaining favor as a solution for quality problems, but many manufacturers struggle with the perceived cost and complexity of implementing new technology.

AIoT and Edge Analytics: a Powerful Combination

Swedish philosopher Nick Bostrom once said, "machine intelligence is the last invention that humanity will ever need to make". AI decision making, with real time communication and data analytics, has the ability to transform the way manufacturers understand machines.

Leverage the Edge - the Benefits of Processing Data at the Edge, Not the Cloud

The edge is an essential layer of the manufacturing technology stack. Machines on the factory floor collect vast amounts of raw data from various sources using numerous protocols, which all needs to be processed quickly to gain actionable insight.

How to manage a complex network of new and legacy equipment

With rapid advancement in automated and connected technologies, managing both new and old equipment simultaneously can be a challenging balancing act.

Securing the OT edge with SASE

Manufacturers have become increasingly reliant on cloud-based resources, such as Software-as-a-Service (SaaS) applications and data migrating from the data center to multi-cloud environments. This requires a new model for secure network access.

10 Fundamental Computer Hardware Needs For Edge Computing

To cope with increasing amount of data, edge computing hardware is being deployed to alleviate the burdens placed on the cloud and data centers. So, what are the computer hardware needs for edge computing? We will answer this question in much detail.

Edge AI technology In Manufacturing Operations

A downside of so much automation is that there is now a heavier dependence on machinery/robots to perform action. For some lines, if one of robot goes down, the entire line does.

What's in Store for Edge Computing Deployments in 2020

During POC projects in the last few years, many organizations have confirmed the benefits that IIoT can bring to a wide variety of industries - and IoT spending is expected to reach $1.1 trillion by 2025, according to IDC.

How to Choose the Right Edge Computer

Choosing the right edge computer is not always easy. Every application has unique requirements that require thoughtful planning, especially for large scale deployments.

Why Edge Computing Is So Crucial for Industrial IoT

Edge computing serves two main purposes: extracting signal from noise by locally processing large volumes of data that are not feasible to send across the internet and providing the ability to process specific things locally where and when latency is a concern.

Records 1 to 15 of 16

Featured Product

Affordable Excellence: The Go-To Tool for Finding Compressed Air Leaks

Find compressed air leaks fast with FLIR's new cutting-edge Si1-LD acoustic imaging camera. Leveraging advanced ultrasonic technology and onboard analytics, this affordable camera pinpoints leaks and quantifies incurred losses even in the nosiest environments. Upgrade your maintenance routine with the cost-effective FLIR Si1-LD - significantly reduce energy costs and increase system uptime. Get Started Today.