Energy Efficiency in Manufacturing and Data Management

Energy consumption is growing exponentially, while energy creation is increasing only incrementally. This imbalance requires innovative solutions. At Delta, we tackle this challenge from both sides-enhancing energy creation while optimizing energy consumption.

Digital Insights: Improving Collaboration Across Sites and Global Teams

Insights are more than data, it's about improving how your teams and production lines work together. Insights are crucial as they let cross-functional teams see the same data and understand the real-time state of the entire operation. Learn more in this Q&A.

Applying ISA-95 in an Industry 4.0 world

Given the criticality of usable data at scale for Industry 4.0, many manufacturers have turned to ISA-95-probably the most commonly recognized data-modeling standard around the world-for guidance.

The Current State of Supply Chain Data Quality

The implementation of strategic data quality capabilities can make or break a business. Many businesses suffer the consequences of risks and excess costs without ever understanding the root cause to be poor data quality or integration.

How Does the New Generation Memory - DDR5 - Change Things?

With more and more data comes the need for storage and fast access which means that technology like DDR5 has never been more important.

5 Ways MDM Can Improve Manufacturing

The often-discussed goal is to have a "single version of the truth" across the organization. MDM is not unique to the manufacturing sector, but it's rapidly gaining ground in that industry.

Records 1 to 6 of 6

Featured Product

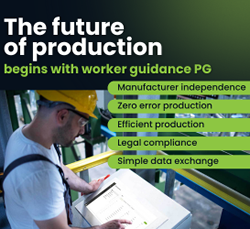

Quality assurance in the manufacturing industry

Efficiency and precision with CSP software. In the highly competitive world of manufacturing, quality assurance is a critical factor for success. CSP offers you state-of-the-art software solutions specifically designed to ensure the highest standards of quality assurance in the manufacturing industry.