KOSF’s key project are the Smart Cubes, which are modular blocks that perform a dedicated task in the automation process, e.g. quality inspection, testing cells, robotic assembly, packaging and many more.

Modular Cubes with Modular Connection System for Smart Factory

Modular Cubes with Modular Connection System for Smart Factory

Case Study from | Staubli

The Korea Smart Factory Association (KOSF) is a federation by the Korean government developing solutions in the field of industrial machinery and process automation. Its main mission is to support small and medium manufacturers that do not have the financial means and know-how to design new smart factory solutions on their own.

Korean know-how for industry 4.0

KOSF aims at providing key technologies and solutions to advance and define the concept of Smart Factory and Manufacturing 3.0 and Industry 4.0. In particular, these solutions enable small and medium-sized enterprises to increase their productivity and gain a foothold in the markets

Modular cubes automatically connect to each other with CombiTac

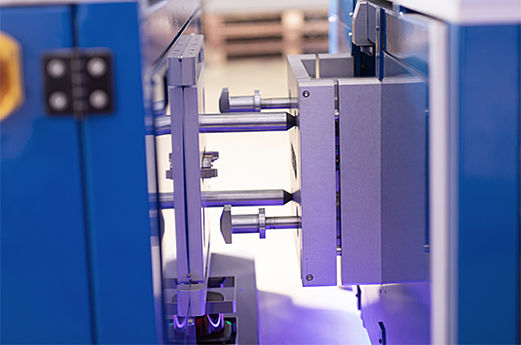

CombiTac with large guiding devices for automatical connection of the cubes

Manual connection with CombiTac

Modularity for Smart Factory

KOSF’s key project are the Smart Cubes, which are modular blocks that perform a dedicated task in the automation process, e.g. quality inspection, testing cells, robotic assembly, packaging and many more. They are an integrated element for smart factories, where prior simulation and modelling of entire manufacturing processes are analyzed in advance, thus optimizing costs and time accordingly. The mobile Smart Cubes are equipped with wheels and can be individually linked together to form a complete process line.

The Smart Cubes

For building the customized production line, the Smart Cubes are remotely navigated to link to each other. Therefore, the technical connection needs to be robust and resist to many matching cycles. The configuration of the connectors has to provide data transfer, signal information for man-to-machine communication (M2M), compressed air and power. As the solution of the Smart Cubes will gradually evolve, the connectors are supposed to allow modular configuration.

KOSF Smart Cubes feature a plate at the left and right side carrying two large guiding devices and two claws grabbing the next cube to pull together and finally interconnect both modules remotely. Hence, the connector needs also to compensate deviation besides being robust, safe and very reliable.

The modular solution for the modular cubes

The modular CombiTac connector system provides tolerance compensation and ensures highest contact reliability when one Smart Cube is interconnected to another. The connection types can be entirely configured as required, whether there is fluid needed or data and signal or any other combination with power. This modular connection solution can be integrated in any construction as panel mount system.

All in one with personal consulting

The solution implemented by Stäubli impressed KOSF by its reliable and stable performance as well as the ruggedness of the air coupling module in the CombiTac. Further it convinced, because the connection is very efficient. The Smart Cubes can be interconnected very quickly and link all medias at one time. The vicinity of the Stäubli engineers and the cooperative development of the best engineering solution to interconnect the cubes supported KOSF’s concept of the modularity of mobile process automation cells. The Smart Cubes benefit from Stäubli’s reliable, robust and modular CombiTac system.

“We highly appreciated the personal consulting of the Stäubli staff and their dedication to our project. The modularity of the CombiTac solution combined with its robustness and reliability is the perfect match for the interconnection of our Smart Cubes”, confirms Chan-Hee Jang, Project manager

APPLICATION

- Market: Manufacturing Industry

- Product solution: CombiTac connection system

- Application: Interconnection of smart factory cube modules

Properties:

- Individually configurable with data (Ethernet), power, M2M communication (Signals), compressed air

- Resistant to high mating cycles

- Tolerance compensation

- Reliable and stable performance

BENEFITS

- Saving of conversion costs by tailor made solution

- Optimized operational costs through reliable and durable connection in challenging environment

- Timesaving coupling process of production cells due to modular connector design

- Customer vicinity of Stäubli engineering contact

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product