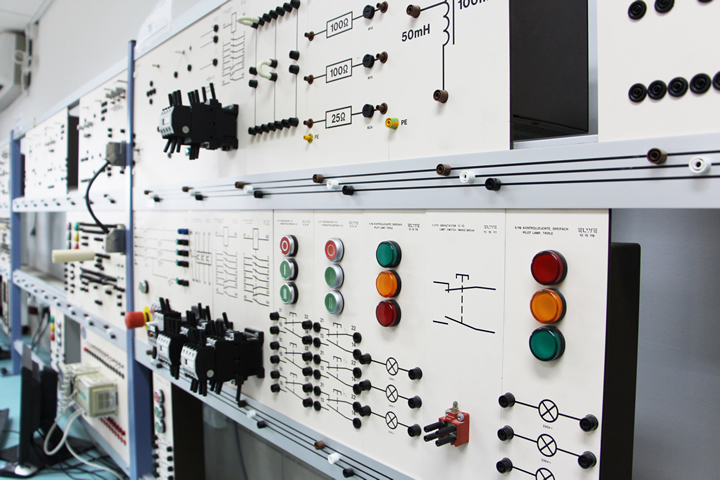

Repurposing and Extending the Life of Aging ATE Systems

ATE stations are specifically engineered to validate the functionality of the units being tested. A substantial investment in testing equipment is necessary, and then… everything changes. Government contracts may not be renewed or could be entirely terminated.

Why you need to know where Smoke Tests fit in Your QMS

How did QA tell when a product failed its burn-in? The product stops working because its electronic circuits overheat and literally burn up. Everybody could tell where QA was located by the smoke rising above it from smoldering circuit boards.

3D Printing Powers Wind Turbine Research At TU Berlin

On average, wind turbine blades are a massive 80 meters long. When it comes to reengineering these towering blades, no other technology offers the freedom, precision, and adaptability to scale parts quite like 3D printing.

More assembly processes in a smaller space and using less energy

The market for electronic controllers for vehicles is growing. The driving forces are electrification and the increasing number of assistant systems. However, this does not change the competitive pressure to which manufacturers are exposed.

Successful Conversion of a Vehicle Assembly With Electric Monorail System

The challenges that arose during the course of the project and how they were overcome are reported by the departments involved. The end result was a system with brilliant production performance.

When Products Fail

Spectacular failures tend to attract much attention. It is simple curiosity as to why it happened and why something was not done to prevent it. One such event was the engine fire on a Boeing 777 flight over Denver in February 2021.

Modular Cubes with Modular Connection System for Smart Factory

KOSF's key project are the Smart Cubes, which are modular blocks that perform a dedicated task in the automation process, e.g. quality inspection, testing cells, robotic assembly, packaging and many more.

How to Go Lean With Your Assembly Line Layout

Every operation has different goals and resources, so what lean looks like will vary. Still, there are some general concepts you can follow to create a lean assembly line.

Determining Cost-Effective Error Recovery in Automation Plants

This article presents a research study that determined the optimal error recovery method from a cost standpoint. And, while this research study only considered cost in error recovery, it shows the potential value of error recovery planning in automation plants.

Improving Efficiency in Counting Applications

Now that counting scales can store information electronically, piece count weights can be measured once and stored, rather than weighed again and again each time a new count must be taken.

Intensive Failure Analysis Optimizes CNC Spindle Performance and Life

Comprehensive failure analysis and detailed documentation are indispensable tools in preventing recurring spindle failures, and can lead to improved performance.

Records 1 to 11 of 11

Featured Product

NORD Delivers Powerful, Reliable Drive Solutions for Demanding Packaging Applications

When you need quality, flexibility and high efficiency, NORD has you covered with complete drive solutions for primary and secondary packaging, end-of-line packaging, and higher-level applications. NORD supports you through the entire life cycle of your drive systems with pre-sales engineering support, online tools, and a global service network. Drive systems for both vertically and horizontally networked technology with all the options for sensor incorporation and integration into the higher-level control system.