Cap Closed! Camera-based Cap Control With Artificial Intelligence

Strong price pressure combined with high quality requirements - the beverage and bottle industry faces the classic dilemma of many industries. This is also the case in the quality control department of a French manufacturer of plastic caps.

Readers Choice 2020: Quality 4.0: The 3 Most Important Technologies for Manufacturers

This article will explain the three technologies, that, based on Boston Consulting Group's Quality 4.0 study - will be deployed by most manufacturers who are planning to improve their quality management.

The Real World Quality Journey

Quality 4.0 blends technology with traditional methods of quality, in order to help manufacturers achieve operational excellence. It leverages technology to collect data enterprise-wide to provide visibility into the complete product lifecycle and manage workflows.

Faulty Takata Airbags Make Headlines Again

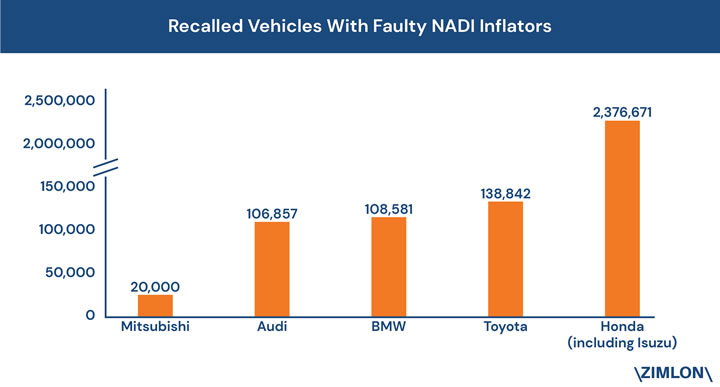

The recalls made in late-2019 was due to defective NADI (Non-Azide Driver Inflators). These defective airbags have inflators that could explode, which the manufacturers have narrowed it down to a faulty seal.

Quality 4.0 Takes More Than Technology

According to a recent report from Boston Consulting Group (BCG), "Quality 4.0 Takes More Than Technology," nearly two-thirds of manufacturers believe that Quality 4.0 will significantly affect their operation within five years.

The Latest Trends Impacting Quality Within Manufacturing Organizations

It's no longer about identifying a problem and reactively taking the appropriate corrective action. It's about pinpointing a potential problem that could occur and applying all of the available data, methods, tools and technology to prevent it from ever occurring.

How Is IoT Data Being Leveraged Today to Improve Quality in the Commercial or Industrial Market?

Every company is concerned about quality, but leading companies are leveraging automated systems and IoT data to test their products and improve quality at a new level. Leaders in this industry include Tesla, Raymond, and Daimler Trucks.

Records 16 to 22 of 22

Featured Product

NORD Delivers Powerful, Reliable Drive Solutions for Demanding Packaging Applications

When you need quality, flexibility and high efficiency, NORD has you covered with complete drive solutions for primary and secondary packaging, end-of-line packaging, and higher-level applications. NORD supports you through the entire life cycle of your drive systems with pre-sales engineering support, online tools, and a global service network. Drive systems for both vertically and horizontally networked technology with all the options for sensor incorporation and integration into the higher-level control system.