Speeding the Industrial Design Process with Modern Calculation Management

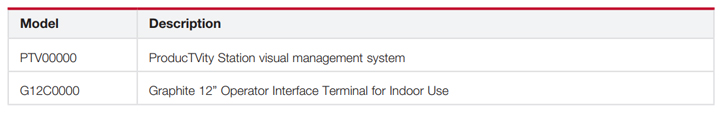

Red Lion Case Study: Blizzard Ski

Case Study: Steel Spring Cup (2 Parts Per Second Zero Defect)

Automotive Parts Supplier Launches IoT Initiative in Six-Week Sprints Powered by Industrial Data

Increased Accuracy and Fulfillment Rates Reduces Training Time and Speed of Products to Customers

Gearmotors Thrive in Tough Corn Processing Application

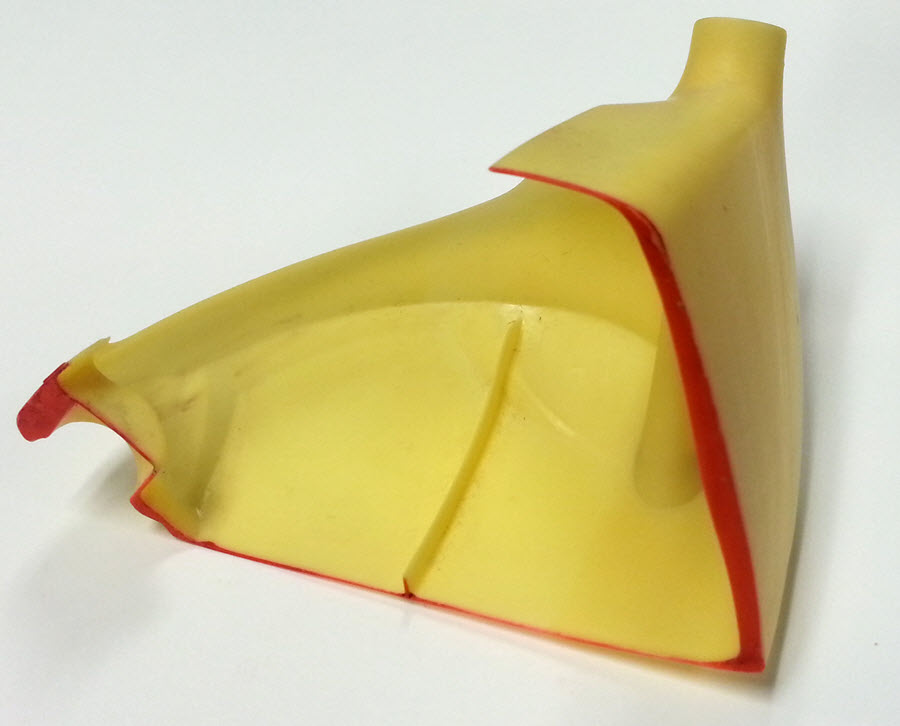

Developing a New Product Using Advanced Manufacturing Technologies

Hole-in-One: Cleveland Golf Case Study

State-of-the-art Motion Control and Electronics for Sorting Line

Sanitary Conveyor System from Dorner Helps Wisconsin Cheese Packer Improve Ergonomics and Packaging Efficiencies

Quick Precise Motion for the Packaging Industry Created by Nook Belt Driven Actuators

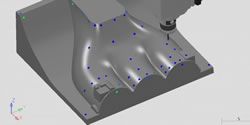

CNC Inspection Software Reduces Time Needed to Machine Composite Parts

Lift Gate Provides Added Flexibility to SmartFlex System

Universal Robots Polishes Paradigm to 50% Production Increase

Unique Hybrid Cnc Tool Solution Uses Beckhoff Controls To Integrate Additive Manufacturing With Standard CNC Machining

Records 31 to 45 of 47

First | Previous | Next | Last

Featured Product

.jpg)