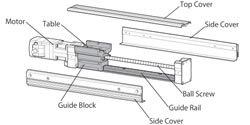

Choose an Actuator That Actually Matches Your Optimized Design

Today, many machine builders are optimizing their machine design first and then selecting an actuator based on that design. Unfortunately, however, many off-the-shelf actuators don't meet their design requirements in an optimal way

Quick Precise Motion for the Packaging Industry Created by Nook Belt Driven Actuators

The wide variety of shapes and thinner bottles created a need for packaging machines to not only be accepting of the different sizes, but also perceptive enough not to damage the new thinner bottles.

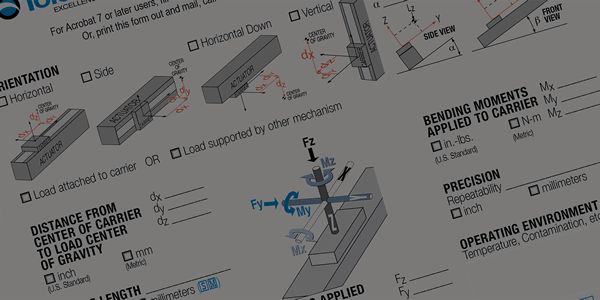

Method for Calculating Moment Loads on Linear Actuators

With the actual equipment, there are various kinds of equipment conditions and driving conditions for electric actuators and cylinders and thus, it is very difficult to explain all the operating conditions.

Records 1 to 3 of 3

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.