How 3D Printing is Paving the Way for Grading Contractor, C.J. Moyna & Sons

At C.J. Moyna & Sons, being on the lookout for disruptive technologies is a part of his everyday routine. When they set on a path to integrate additive manufacturing into their daily processes, the work became easier for C.J. Moyna & Sons and their sister companies.

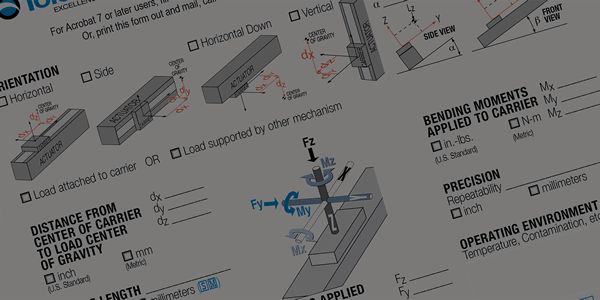

Choose an Actuator That Actually Matches Your Optimized Design

Today, many machine builders are optimizing their machine design first and then selecting an actuator based on that design. Unfortunately, however, many off-the-shelf actuators don't meet their design requirements in an optimal way

Control System Migrations | Procurement Specification & Vendor Selection

From deciding whether to handle tasks internally or outsource them, to selecting the right vendor(s) and structuring procurement, each decision plays a vital role in the overall success of the project.

Benefits of Gearbox Customisation for OEMs

A customised gearbox not only increases the life-span of existing hardware, but it can be designed to evolve and develop alongside the needs and goals of the business.

3D Printing Platform Could Shape the Future of Spare Part Production

The use of 3D printing technology to enable the fast availability of spare parts - when needed, where needed, in exactly the right quantity needed, is now, thanks to German company Replique, becoming a reality.

Records 1 to 5 of 5

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.