Keyence Wide-area CMM Helps Machine Shop Diversify Into Aerospace Market

Although the checking of long components for the oil and gas sector was Coastal Machine's original requirement for the Keyence WM, the CMM's capability and versatility led to the company finding fur- ther uses for the device.

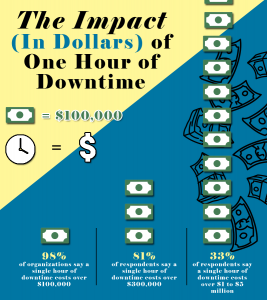

Big Picture Benefits of a CMMS

CMMS (Computerized Management Maintenance Software) is the ultimate tool in a maintenance technician's tool belt - a cure for the tedious tasks and daily issues of a maintenance department.

Records 1 to 2 of 2

Featured Product

ResinDek® TRIGARD® ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC® (www.resindek.com) created the TriGard® ESD Ultra finish for its ResinDek® engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.