Lessons from World War II on Manufacturing and the COVID-19 Pandemic

A look at manufacturing and the COVID-19 pandemic shows the comparison to WWII is an apt one. From victory gardens to discussions of shared sacrifice to ramping up production of critical supplies, the parallels between the health crisis and WWII are hard to ignore.

As The Electronics Manufacturing Industry Slowly Recovers From The Pandemic, What Can We Learn?

Within the realm of manufacturing, one thing is abundantly clear: supply chains are intrinsically tied and vulnerable to just about everything in our world today.

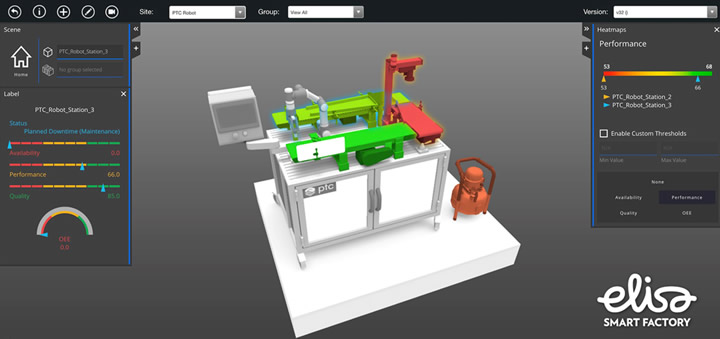

COVID-19 Accelerates Digitalization in Manufacturing But Data Silos Must Go!

When the manufacturing industry emerges out of the COVID-19 pandemic, we will see the rapid trend of digitalization. However, to achieve maximum success - this will only happen if manufacturers finally deal with the challenge of data silos!

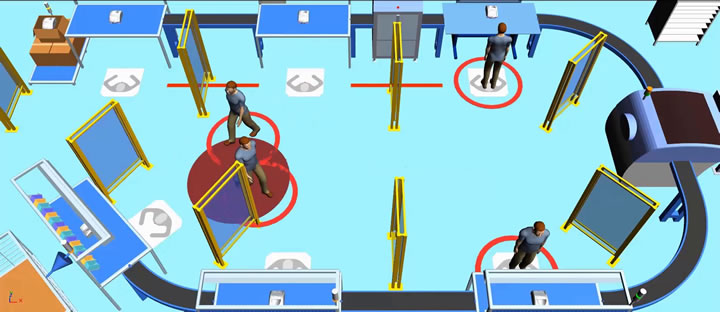

Siemens introduces workplace distancing solution to manage "next normal" manufacturing

Using proven software and hardware, Siemens has developed a unique workplace distancing solution that helps manufacturers to simulate and manage employee exposure risks while enabling productivity throughout their facilities

3D modelling technique for fast-track face shield production

Using stacked model data, the technique can dramatically increase 3D printing output, assisting in producing face shields for healthcare workers fighting COVID-19.

Five Strategies for Finding New Suppliers Outside of Your Regular Network

Whether it is because they are switching production from clothing to personal protective equipment (PPE) or because their regular suppliers are suddenly unavailable, many procurement teams are now searching for new suppliers under significant time pressure.

How to Keep Manufacturing Employees Safe During Coronavirus

You can find plenty of general health guidelines, but you need to know actionable specifics. OSHA released a list of safety measures for manufacturers, but it doesn't go into much detail.

How digital connects CNC businesses in the age of the pandemic

Traditional CNC business models and organisations are currently under threat. The COVID-19 outbreak has made it clear just how vulnerable the complex, global manufacturing supply chains are.

How the IoT Can Help Supply Chains Excel Under Stress

When attached to shipment containers, the IoT affords manufacturers insight into what's happening at each point of the supply chain, thereby assuring their products reach their destinations in a safe and timely manner.

How the Coronavirus Is Changing Equipment Manufacturing

Companies from various sectors are ramping up production or changing what they make to help the world cope with the coronavirus crisis. Here are several examples.

How Manufacturing Can Rise from the Ashes of the Old Norms, Stronger and Better

From challenging times comes opportunity, and British manufacturers must embrace this in order to navigate through the 'old norms' into the 'new now'. Below I explore the key trends emerging in the sector.

Will Manufacturing Recover After Coronavirus? China Says 'Yes'

While nothing is absolute yet, there have been promising signs at the heart of the outbreak. As China's production starts to pick up steam again, it could signify the revitalization of the industry.

Manufacturers Step Up to Produce Personal Protection Equipment (PPE) and Respirators in a Hurry

Shortages of Ventilators and PPE has become a worldwide problem. Many of our manufacturing partners and other companies are stepping up to help with some innovative solutions. Here are just a few of the efforts being reported to us.

COVID-19 takes digitizing the factory floor from inevitable to urgent

Amidst massive uncertainty, one thing is crystal clear: business-as-usual is no longer an option. Now is the time when digitizing the factory floor becomes critical for survival.

Records 1 to 14 of 14

Featured Product

MOTION CONTROLLERS FOR MINIATURE DRIVES AND MICRODRIVES

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new Motion Controller is ideal for integration in equipment manufacturing and medical technology applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to approx. 100 W and is suitable for DC-motors with encoder, brushless drives or linear motors.