Getting a Grip on Automation - Demand for Robotics Gains Steam

One of the primary drivers of the increased use of automation is the lower cost of robotic solutions. While some manufacturers might still be spooked by cost, automation doesn't have to break the bank.

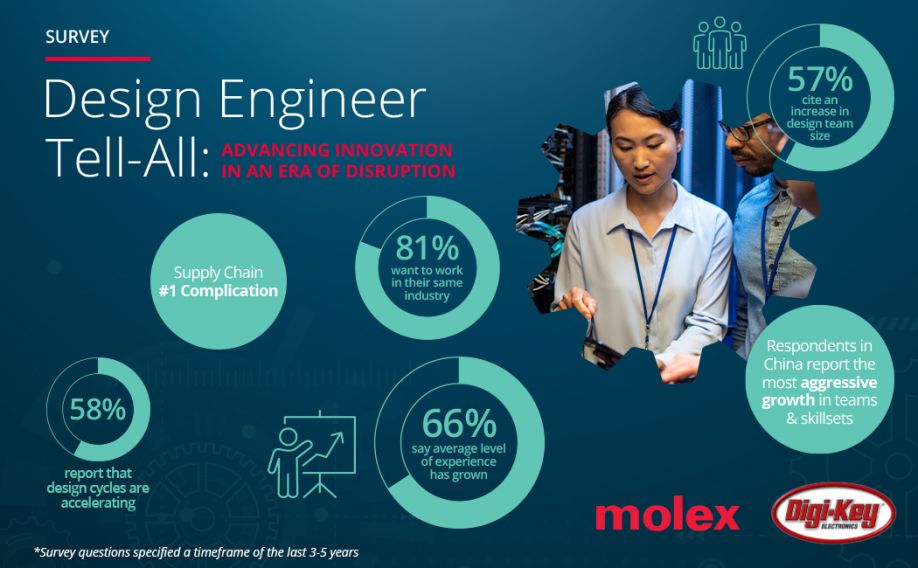

Molex Announces Results of Global Design Engineering Innovations Survey

According to 65% of those polled, improvements in design tools, tech innovation and new design methodologies have simplified efforts over the past three-to-five years. Still, a multitude of factors continue to hinder design engineering progress and innovation.

PLM-Based Engineering

Today, engineers have a lot more control over the direction of their products, and PLM is where they reflect these decisions. PLM is the only data repository where someone can get a holistic view of the entire product and its history of changes.

Manufacturing Impact: Rising Consumption of Entertainment Drives Demand For 3D Animated Content

The augmented demand for the technology from several industrial verticals due to the increasing use of simulation in the design of industrial tools by OEMs has facilitated the penetration of 3D animation solutions worldwide

BEVERAGE MANUFACTURER TRANSFORMING INTO A DIGITAL OPERATION

The company's unique objectives required PSbyM to modify its own processes for the six-month engagement. First, a far more detailed assessment of operations was completed by practitioners, including focus groups and deep dives into equipment-design elements.

Speaking the Language of Manufacturing Engineers

Manufacturers of highly configurable products want to maximize engineering resources. By capturing knowledge and decision-making, the newest best-in-class engineering automation software speeds development of subsequent design iterations.

WCX World Congress

Mobility engineers will learn how to address the energy and environmental challenges of vehicles through the application of next generation electrification, emissions reduction, and lightweighting technologies.

How 3D Printing Streamlines the Engineering Workflow

Michael Molitch-Hou for Engineering.com: The desktop 3D printing space has become an interesting one in the last year or so, as manufacturers shift the focus away from consumers and towards professional and industrial users. The technology has proven that it may not quite be ready to produce consumer goods for every household—or perhaps households aren't quite ready for 3D printing at home. Those in the industry know, however, that low-cost 3D printing is still a powerful technology, if not for fabricating home goods, then as an early design tool and, in some cases, even for short-run manufacturing. Cont'd...

Records 1 to 8 of 8

Featured Product

Prototek IQ - Digital Manufacturing Services

Prototek IQ is our new instant quoting platform that simplifies your manufacturing process. With just a few clicks, you can get accurate quotes for 3D printing and CNC machining, which are currently two different platforms. Our easy-to-use interface helps you make smart choices. Use Prototek IQ to improve efficiency and streamline speed to market. We invite customers with experience in large projects, 3D printing, and CNC machining, as well as those with repeat orders, to try our instant quoting platform. You can choose our engineer-assisted quote option if you have unique needs, such as high quantities, specific quality standards, fast delivery, or special finishes.