BEYOND THE SURFACE: THE POWER OF DENSITY DETERMINATION IN ADDITIVE MANUFACTURING

In this article, we will delve deep into the significance of density determination in AM, exploring how it assesses the quality of metal 3D printed parts and the impact it has on various industries.

Amazing Color Variety

Plastic can be found everywhere in our world, and injection molding is the universal, cost-effective production method used to form it into almost any shape: The raw material, plastic granulate, is heated until it is flowable and is then injected into a mold.

How Effective Recycling Practices Can Impact the Redistribution of Global Resources and Wealth

The next leap forward in sustainability is going to be reclaiming the resources contained within the garbage and providing feedstock back into the manufacturing process.

Smart Plastic Materials for Flexible Electronics Could Be a Game Changer

Researchers have worked over the last few decades to develop the next generation of electronics. The ultimate goal is to make components flexible and conformable, allowing new types to hit the market.

Thermoset vs Thermoplastic: Definition, Processes, and Differences

This article gives a detailed thermoset vs thermoplastic comparison. Although there are many similarities between thermoplastic and thermoset, some differences are also present.

New Solutions for Materials Manufacturing Reduce Environmental Impact in Construction

While zero-emissions equipment and waste reduction strategies are crucial, sustainability is complex, involving far more factors than construction work itself. The manufacturers that produce building materials must also improve for the industry to become truly sustainable.

Copper Shortages Present New Manufacturing Challenges in 2022

While the refined copper market had a 142,000-ton surplus in 2020, experts predict that to fall to a 219,000-ton deficit by 2025. This shortage has already started to take effect and will have increasingly severe consequences as it continues.

Powering Additive Manufacturing with an Environmental and Social Impact Commitment

Structured ESG and strategic, measurable sustainability programs are unlocking the deep value behind "doing well (profitability) by doing good (sustainability)."

Rethinking material usage - How 3D printing enables dematerialization

3D printing makes it possible to introduce different materials into production that offer a lower embodied energy. In many applications, polymer or composite materials can offer the same strength and durability as metals.

How to Use Supports

Most entry-level 3D printers work by extruding material, and while this has lots of cost and safety advantages, it does come with some limitations. Creating a part with extreme overhangs, arches, or angles can be a challenge. Supports make printing these geometries possible.

American Steel

Faced with tight quarters on a gearbox application, Texas-based machine builder turns to NORD DRIVESYSTEMS for help.

Massachusetts Metalcaster Established Over a Century Ago Leaps Forward with 3D Mold Printing

A growing number of companies within the sand casting industry are adopting 3D sand printing to produce high quality parts without tooling. The technology to 3D print molds without changing the actual sand casting process itself is a major advancement for the industry.

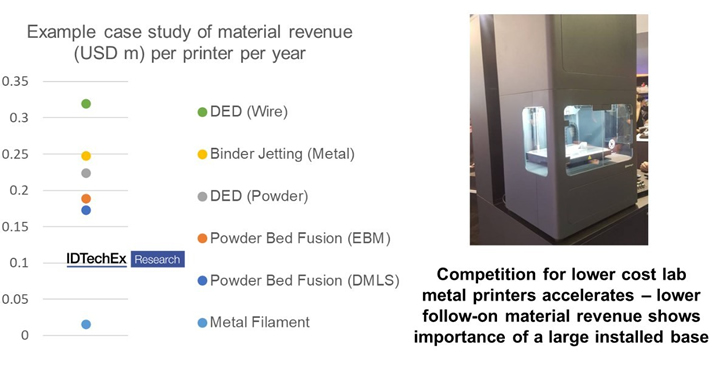

Metal Additive Manufacturing: The Cheaper the Better, asks IDTechEx

Metal additive manufacturing currently services high-value industries, most of the printers sold are powder bed fusion and can cost over $1m with expensive powder feedstocks.

Successful use of Carbon-composite Windform® XT 2.0 and professional 3D printing in the construction of 1P PocketQubes flight-ready

It is the first time that entire PocketQube functional prototypes flight-ready are manufactured using a Carbon-reinforced composite material - Windform® XT 2.0 - and Laser Sintering process.

World's first 3D printed FRP footbridge paves way for circular composites

The circular composite footbridge is made from a fiber reinforced thermoplastic called Arnite® which combines high performance with circularity.

Records 1 to 15 of 32

Featured Product

KEB VFDs for High Speed Motor Control

KEB's VFDs are the key to unlocking peak performance in your high-speed machinery. Engineered for precision control, even without feedback sensors, our F6 and S6 drives utilize advanced software and high-frequency output. This ensures smooth operation, reduced vibration, and optimal efficiency. Whether you're building turbo blowers, power generation systems, or other high-speed applications, KEB VFDs deliver the reliability and performance you need.

.jpg)

.jpg)