Navigating the Frustration of Unreliable Heat Sealers in Automation

This article delves into the challenges posed by unreliable heat sealers and explores the solution of real-time thermal seal inspection systems to alleviate these concerns.

Amazing Color Variety

Plastic can be found everywhere in our world, and injection molding is the universal, cost-effective production method used to form it into almost any shape: The raw material, plastic granulate, is heated until it is flowable and is then injected into a mold.

Exploring Additive Manufacturing Opportunities: Optimizing Production with Hyundai Lifeboats

The journey to finding success in AM is no simple task. Materialise Mindware, our 3D printing consultancy team, outlined the various steps to steer customers through this journey. Discover how they guided Hyundai Lifeboats through the first phase.

Lack of Automation is Holding Additive Back

Additive Manufacturing (AM) has the potential to rewrite the economics of production. It offers the ability to create more complex geometries and structures than is possible with traditional methods, enables greater efficiencies and performance.

Tackling Obsolescence With Additive Manufacturing - 3D Printed Spare Parts Is Revolutionizing Manufacturing

When obsolete components break, it can be hard to find like-for-like replacements. Managing obsolescence is therefore critical since the breakage or malfunction of obsolete components exposes the business to risk of costly downtime.

Automating Post-Production to Scale-Up Additive Manufacturing

Unshackled by the limitations associated with traditional production processes, AM has made the leap from prototype to end part production and continues to open up exciting opportunities around localised production, digital inventories and on-demand manufacturing.

3D Printing Technology Comparison: SLA vs SLS

In this article, we'll discuss the main similarities and differences between two of the most established processes in 3D printing - stereolithography (SLA) and selective laser sintering (SLS).

Innovative electric race car part shows potential for Electron Beam Melting in automotive

For the past three years, the NCAM's DRAMA research project has helped build a stronger additive supply chain for the UK's aerospace sector - an industry which has the largest number of small and medium sized enterprise (SME) companies in Europe.

Trends for 3D Printing in Manufacturing

There's no question that additive manufacturing will continue growing in the coming years. Some experts expect the 3D printing industry to surpass $20 billion by next year, but what will that look like?

ERIKS: Working Clean, Certified, and in Control with 3D Printing

ERIKS offers technical components and related services to all sections of industry. And by adding 3D printing technology to its workflow, ERIKS is able to provide its customers with a service that holds the potential to shake up industries around the globe.

Successful Mission of TuPOD, 3D Printed Innovative CubeSat

There is no doubt that 3D Printing is shaping our societies. Its future is evolving very fast and, although its impact on different sectors is still to be defined, many industries are leveraging 3D Printing technologies for their goals.

Optimising Performance and Manufacturability for Additive Manufacturing

As there are more and more success stories associated with the use of AM as a production technology, scrutiny on the process is becoming increasingly forensic in nature.

Additive Manufacturing for Production: Benchmarking Against Traditional Alternatives

For a growing number of applications, 3D printing for batch production offers clear economic and added-value advantages- acting as a spur to innovation and enabling the production of end-use products impossible or uneconomical to produce with the use of alternative methods.

CRP Technology and Windform® Materials for 3D Printing are Driving AM Revolution

Some of the most advanced industry - as Automotive - are experiencing a renaissance not seen before, which is driving engineers to find new, innovative, cost-effective solutions using professional 3D Printing, mainly.

Achieving Peak Performance in Elite Cycling and Beyond

The rapid prototyping and 3D printing plastic parts for wind tunnel testing became a well-established model but Katsanis wondered "why not do this with metal"?

Records 1 to 15 of 45

Featured Product

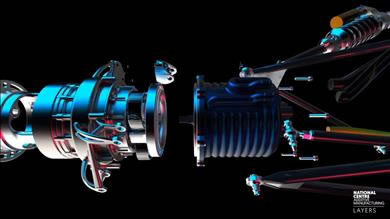

PI USA - Steering light beams: Pros and cons of different methods

Optical system designers utilize tried-and-true technology like galvo scanners, voice coil-driven steering mirrors, kinematic mirror mounts, and gimbal mounts. This article describes strengths and limitations of these technologies and looks at other light steering methods.