DSM launches I AM Tomorrow Challenge to drive innovation in 3D printing

Launched in collaboration with HighTechXL, Hexagon, and Ultimaker, the challenge offers select companies a spot in a ten-week acceleration program designed to launch or mature their businesses.

STANLEY+Techstars Accelerator Announces Second-Annual Class

- 2019 Accelerator continues focus on additive manufacturing and expands to include sustainable packaging solutions.

- Selected companies will relocate to Stanley Black & Decker's new Manufactory 4.0 Center in Hartford, CT for three months

The Enterprise Factory And The Smart City

Adi Gaskell for Forbes: Such a network ensures you not only have the technological skills required but also the cultural and softer factors that are so important.

Records 1 to 3 of 3

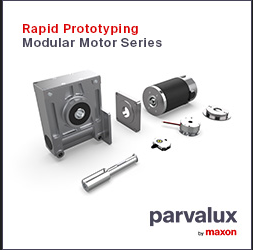

Featured Product

Rapid Prototyping with the Modular Motor Series

Quick to configure. Quick to build. Quick to deliver. Parvalux understands the importance of getting product in the hands of customers quickly and efficiently. The Modular Range does just that allowing customers to configure their own solution, selecting motor and gearbox, adding encoders and brakes to create a solution perfectly suited for their specific applications such as conveyor belt systems, picking systems, parcel sorting equipment, pallet shuttles and automated storage and retrieval systems (ASRS). Read our modular range guide for specifics.